About VMAC

The Leader InCompressed Air Innovation®

VMAC designs and manufactures the most innovative mobile air compressors and multi-power systems available.

We do this with hard-working, dedicated people who devote their working lives to improving the mobile air industry. VMAC coworkers put their skills to the test every day, constantly pushing boundaries in the pursuit of excellence.

We build every VMAC system in-house with the promise that it will work as hard as you do, and we back this promise with our VMAC Lifetime Warranty (Limited).

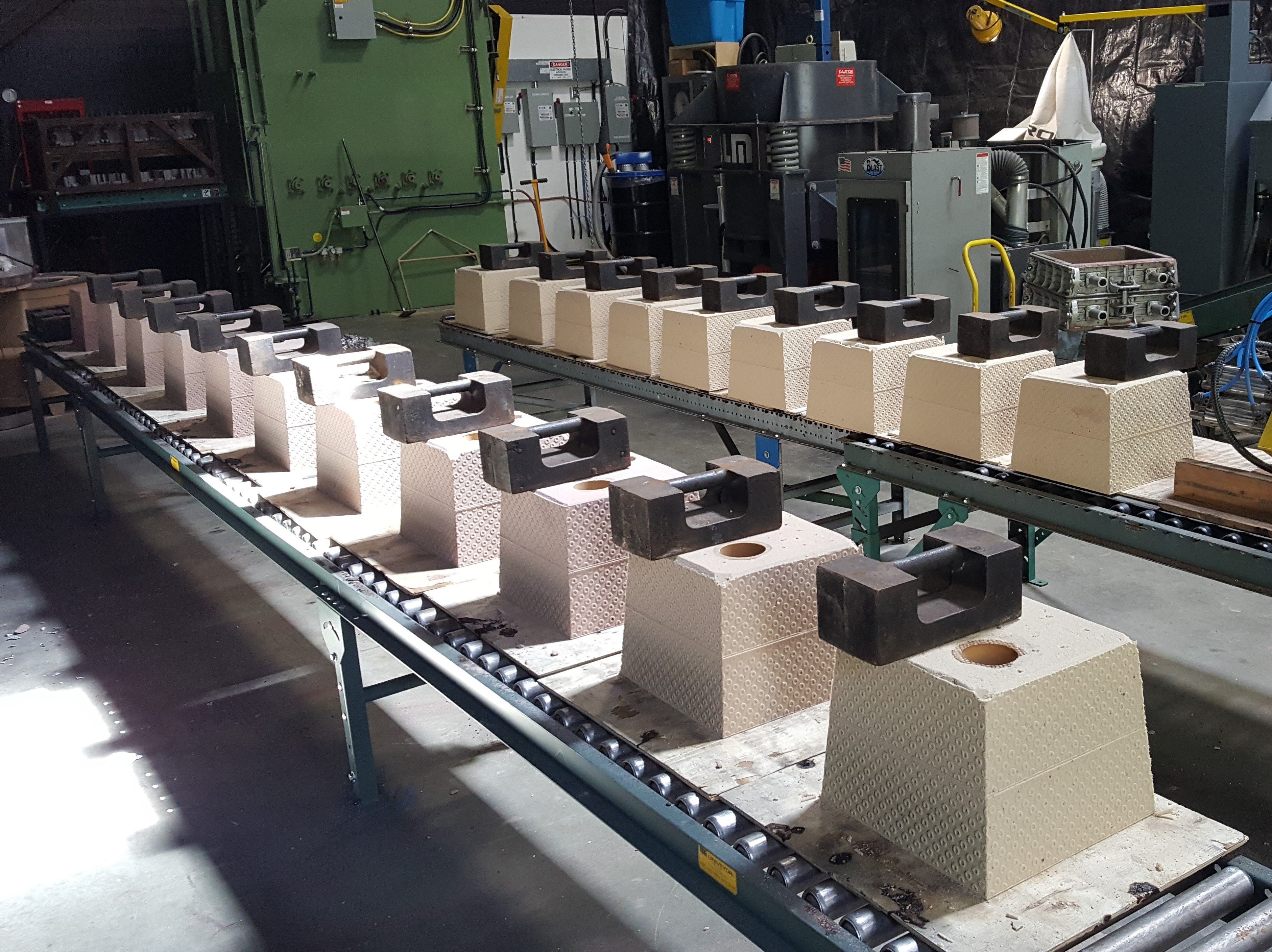

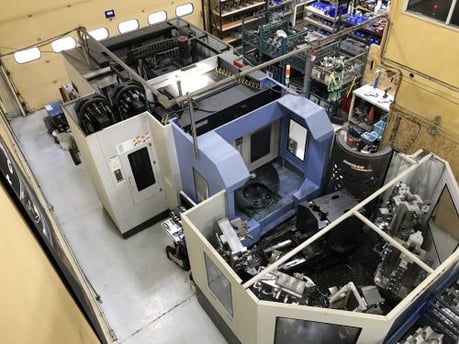

On-SiteManufacturing

VMAC is one of the only authentic air compressor manufacturers in North America. We design, engineer, and manufacture our air compressors and multi-power systems in-house, at our 44,000 ft² headquarters in British Columbia, Canada.

We craft our own rotors and parts using an in-house foundry, CNC machines, and other specialized equipment. Investing in our own machines and parts creation allows us to refine our products at will while maintaining the utmost quality.

Our individual components are then assembled on-site into VMAC air compressor and multi-power systems. Every complete unit is tested, then packaged up and shipped out.

Our TalentedTeams

VMAC uses a cross-disciplinary approach to innovation and invention. That’s why you’ll frequently find our employees collaborating across departments, sharing ideas, and working together to solve challenges of every size. We sincerely believe our ideas are better when we borrow our perspective from numerous disciplines and that’s reflected in our high-quality products.

Our 180+ employees come from a variety of backgrounds and specialties, including:

- Engineering

- Metalworking

- Mechanics

- Machining

- Fabrication

- Supply Chain

- Tech Support

- Finance

- HR

- Sales & Marketing

- Quality Control

ISO 9001 & ISO 14001Certified

VMAC is an ISO 9001:2015 and ISO 14001:2015 certified company, and we take those certifications seriously.

VMAC’s ISO 9001:2015 certification reflects our outstanding attention to quality management, standardization, and continuous quality improvements. From the way we organize our shelves to our endless re-invention of the best mobile air compressors on the market, we are always pushing ourselves to be even better.

VMAC’s ISO 14001:2015 certification recognizes VMAC’s exceptional attention to environmental management systems in accordance to international standards. VMAC strives to minimize the environmental impact of everything we do, which includes responsible sourcing, reducing waste, assessing VMAC’s environmental impact, and considering the lifecycle impacts of VMAC products.

LeanEnterprise

VMAC designs and manufactures the world’s most innovative, compact, and powerful mobile air compressors and multi-power systems available. Steeped in a culture of continuous improvement, VMAC has embraced the lean enterprise methodology throughout operations, far beyond just manufacturing. From the engineering department to the manufacturing facilities, to the shipping, logistics, finance, HR, marketing, and sales departments, each coworker and team plays an integral role in VMAC’s lean culture.

What Is Lean At VMAC?

Lean enterprise goes by many names, including lean manufacturing and Six Sigma, but at VMAC it’s simply referred to as lean.

Lean is best described as the ongoing pursuit of removing waste from an organization’s manufacturing process. Driven by the goal of customer satisfaction, VMAC is constantly striving to produce a product of the highest quality, at the lowest cost, and with the shortest delivery time. Simply put, lean drives VMAC to maximize value while minimizing waste. This benefits the VMAC organization, but also passes value on to our customers in the way of quality, reliability, durability, ease of use, service level, and more.

VMAC’s lean journey is constantly evolving, as improvements can always be made.

VMAC’s Purpose &Core Values

Purpose

To carry forward the innovative spirit established by our founders through our products, the superior customer service emphasized in our every relationship and the family values core to how we do business every day.

Our core values serve as the ethical compass that prescribes how we must act to achieve our purpose.

Core Values

- We place the safety of our coworkers and products above all else.

- We treat customers, coworkers, and suppliers with respect at all times.

- We must be profitable to be sustainable.

- We lead the market by innovating with a deep understanding of product design.

- We continuously improve our processes and products to provide maximum customer value.

- We are accountable to ourselves and our teams.

- We aren’t afraid to fail. We must test our ideas and learn to succeed.

- We persevere as long as a cause remains worthy.

VMAC Unique Entity ID &CAGE Code

VMAC Global Technology Inc. is proud to be registered with SAM.gov and to hold an active Unique Entitity ID (formerly DUNS) and CAGE code. These registrations demonstrate VMAC’s commitment to transparency, reliability, and financial stability.

AirInnovated®

VMAC has developed revolutionary mobile air compressor systems, using a spirit of innovation. With complete in-house control of our product design, engineering, and manufacturing in North America, VMAC will continue to work with our industry partners to develop and release innovative products that empower our customers to work more efficiently, sustainably, and profitably. VMAC is committed to maintaining its position as the leader in compressed air innovation.

VMAC Air Innovated Timeline

| 1986 – Company starts in Kitchener, ON, designing for the Department of National Defense |

| 1987 – Atom Machine Shop opens after military contract ends |

| 1988 – Atom Machine Shop develops bracket for vehicle-integrated air compressor |

| 1990 – Company moves to Nanaimo, BC, and rebrands as VMAC |

| 1995 – VMAC releases Throttle Commander, the world’s first engine throttle control for Ford light duty trucks |

| 1996 – VMAC releases reciprocating ALM Hydraulic Air Compressor |

| 1997 – VMAC releases UNDERHOOD® 70 Air Compressor (formerly “VR7000/VR70”) |

| 2002 – UNDERHOOD® 150 Air Compressor (“VR140”) is released |

| 2004 – VMAC begins manufacturing proprietary rotors for screw compressors |

| 2005 – H60 Hydraulic Driven Air Compressor (“PREDATAIR”) is released |

| 2008 – H40 Hydraulic Driven Air Compressor (“PREDATAIR”) is released |

| 2011 – D60 Diesel Drive Air Compressor released (“RAPTAIR”) |

| 2013 – VMAC launches its first Multifunction Power System (“RAPTAIR-MF”) |

| 2014 – UNDERHOOD® 30 ("UNDERHOOD LITE") is released |

| 2015 - VMAC formalizes its OEM division, which creates custom air solutions for industrial engine applications |

| 2015 – VMAC releases the G30 Gas Driven Air Compressor |

| 2016 – VMAC is first to market with a Direct-Drive PTO air compressor, the Direct-Transmission Mounted (DTM) air compressor |

| 2016 – An in-house foundry is installed at the VMAC facility, enabling VMAC to cast its own parts |

| 2017 – VMAC receives ISO 9001:2015 certification |

| 2018 – VMAC launches the DTM70-H, a Direct-Transmission Mounted PTO driven air compressor with hydraulics |

| 2018 – UNDERHOOD® 40 for trucks and vans replaces the UNDERHOOD® 30 |

| 2019 – VMAC is formally recognized as Air Innovated® by the U.S. national trademark office |

| 2019 - VMAC releases 6-in-1 Multifunction with CAT Power engine |

| 2020 – VMAC releases vertically stacked G30 Gas Driven Air Compressor |

| 2021 – VMAC develops e30 Electric Air Compressor prototype for feedback from key partners |

| 2022 – VMAC releases G30+Gen Gas Powered Air Compressor/Generator |

| 2023 – VMAC releases 5-in-1 Multifunction with Honda gas engine |

| 2023 – VMAC receives ISO 14001:2015 certification |

| 2023 – VMAC secures UNDERHOOD® registered trademark |

OurMemberships

American Rental Association (ARA)

American Society of Quality (ASQ)

Association of Equipment Manufacturers (AEM)

Association of Professional Engineers And Geoscientists of BC (EGBC)

Automotive Industry Action Group (AIAG)

Canadian Manufacturers & Exporters (CME)

Green Truck Association Member Verification Program (GTA MVP)

International Certification Management, ISO 9001:2015 & ISO 14001:2015

NTEA Member Verification Program (NTEA MVP)

Project Management Institute (PMI)