60 CFM Hydraulic Air Compressors

The 60 CFM VMAC hydraulic air compressor is the best choice for fleet managers and owners requiring hydraulic-powered compressed air for continuous duty applications and tools.

The powerful rotary screw air compressor is ideal for operating medium to large sized air tools. The compact design allows it to fit on trucks and specialty equipment with limited available space.

Applications

Common jobs that use the compressor system:- Mobile heavy duty mechanics

- Mobile tire service technicians

- 24/7 roadside repair technicians

- Medium to heavy duty lube trucks

Commonly used tools:

- 1” impact wrenches

- 60 lb jackhammers/pavement breakers

- Backfill tampers

- Vertical/horizontal grinders

- OTR tire inflation

Free Up To 8 Cubic Feet

VMAC H60 air compressors free up to 8 cubic feet on the truck deck. Systems are designed and engineered to be compact for service trucks and applications where space is limited.

Decrease Truck GVW By Up To 240 lb

VMAC’s 60 CFM hydraulic air compressors reduce truck GVW by as much as 240 lb, because VMAC designs systems with lightweight materials and integrated components. Choosing a lightweight air compressor means you’ll be able to add more tools and equipment to your truck, carry more materials, or take advantage of better fuel economy.

Up To 60 CFM, 100% Of The Time

H60 air compressors use patented rotary screw technology that can operate intermittently for smaller jobs, but are designed to run at 100% duty cycle without stopping, so operators don’t have to wait for their air compressor to fill up a bulky air receiver tank. This maximizes tool performance and eliminates downtime by keeping operators working.

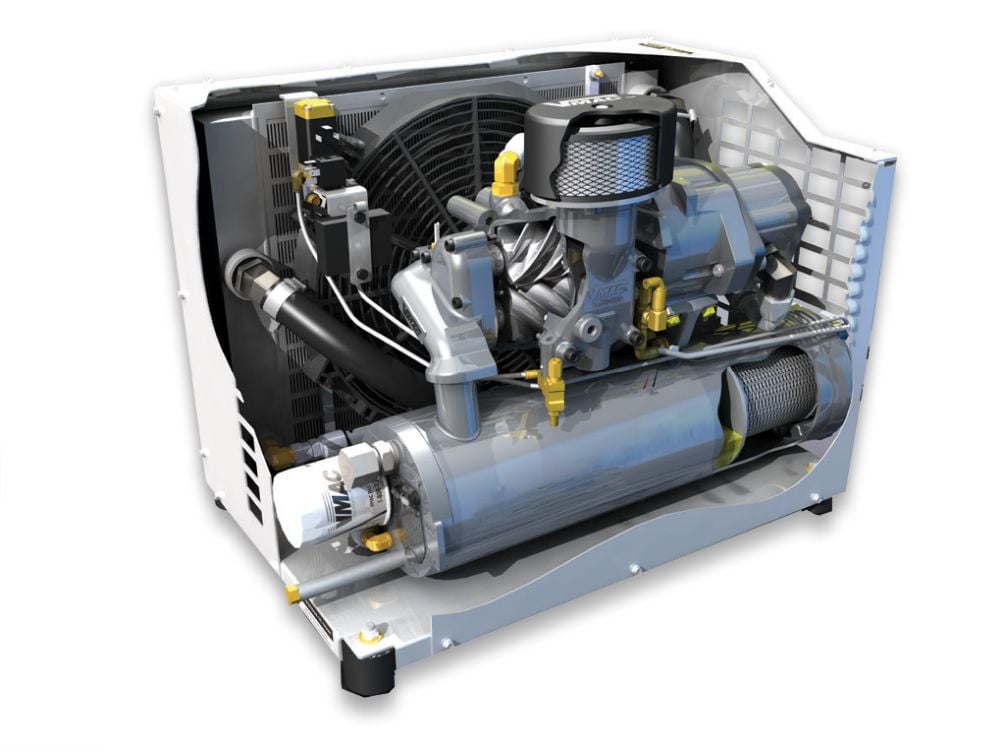

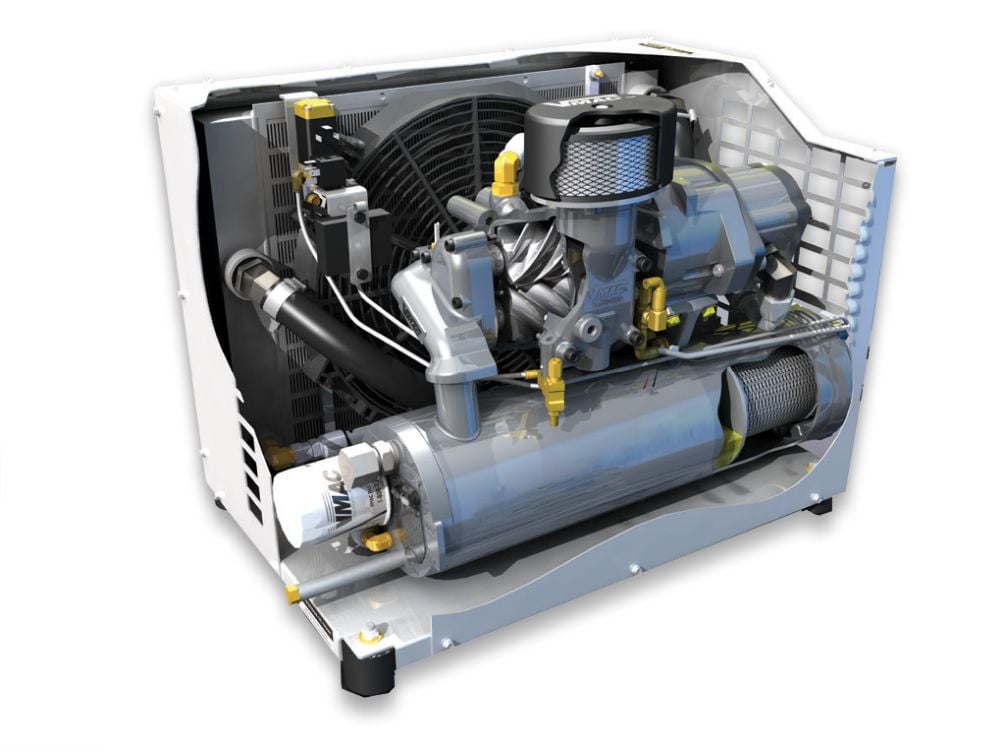

Integrated Hydraulic/Compressor Oil Cooler

12V activated fan, turns on/off automatically to adapt to hydraulic and compressor oil temperature

Digital Control Module

Controls system operation and stored settings

VMAC Air Compressor

Oil-injected rotary screw; direct-driven; 40-60 CFM @ 100 psi; 100% duty cycle; up to 150 psi

Digital Display Box

LCD for on/off controls, observing system status and adjusting parameters, mounts where needed on truck

Hydraulic Manifold

Controls flow of hydraulic oil through the system

Air Discharge

Includes check valve

Air/Oil Separator Tank

Separates compressor oil from compressed air

H60 Hydraulic Air Compressors Specifications

- 40-60 CFM @ 100 psi (150 psi max)

- Direct-driven, 100% duty cycle, VMAC oil-injected rotary screw

-

14-21 GPM; open center hydraulic circuit

- 2,450 psi; 3,000 psi hydraulic pump recommended

- Approximately 160 lb (73 kg)

- 24.0” (l) x 16.5” (w) x 18.0” (h); 61.0 cm (l) x 41.9 cm (w) x 45.7 cm (h)

- Integrated hydraulic / compressor oil

- 12V fan

- #12 ORB Inlet, #16 ORB Outlet

- LCD digital control box with hour meter, service reminders, and error messages

- Live monitoring of air pressure, hydraulic and compressor temperatures.

- Automatic cold climate protection

- Automatic warm-up mode extends system life

- Standby Mode, turns system off and on depending on air use

- Compressor/Hydraulic overheat protection

- Cooler bypass check valve

- Overpressure shutdown

- Automatic rapid blow-down valve on tank

- 200 psi pressure relief valve

- 2,800 psi hydraulic pressure relief valve

- Automatic cold climate protection

- Minimum 6-gallon air receiver tank recommended for proper operation of all functions

- White

- Black

- Custom (Fleet orders only)

- Two years on all major components; VMAC air ends are covered by VMAC’s Lifetime Warranty (Limited).

- For more information about VMAC’s Warranty, visit www.vmacair.com/warranty.