3 Types of Air Compressors For Your Industrial Engine Application

You’ve decided that your current application needs compressed air. You’ve also figured out how much air you need, how to drive the compressor, and what engine you will use to power it. Now it’s time to decide what air compressor best suits your needs!

There are three styles of air compressors commonly found in mobile industrial applications:

- Reciprocating/Piston Compressors

- Rotary Screw Compressors

- Rotary Vane Compressors

Each of these air compressors has benefits and challenges, which we will break down in this article.

Reciprocating Compressors

Reciprocating compressors are the most common air compressors found in mobile applications and are the type most people are familiar with. There are numerous manufacturers and suppliers worldwide, providing an array of options.

Benefits

- Low initial cost

- Easiest to service & rebuild

Of the three compressor types, reciprocating air compressors generally have the lowest initial purchase price and are suitable for low-duty cycle operations. Unlike many vane and screw compressors, most reciprocating compressors can be serviced or rebuilt in the field with simple hand tools.

Challenges

- Large & heavy

- Many moving, wearable parts

- Higher air temperature

- Excessive pulsation

- Requires an air receiver tank

Reciprocating compressors are typically the largest and heaviest when compared to compressors of equal CFM. They have the most moving parts and, like the vane compressor, experience increasing amounts of oil carryover. Because of how reciprocating compressors produce air, more after-treatment is required to reduce air temperatures and pulsation before the compressed air reaches your tools and equipment. An air receiver tank is also required with a reciprocating air compressor and takes up additional space.

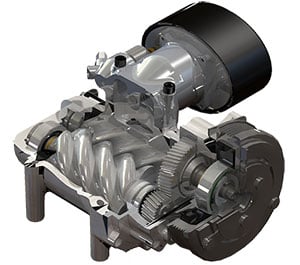

Rotary Screw Compressors

Traditionally, rotary screw compressors were used in stationary applications and were not widespread in mobile applications. However, times have changed! Rotary screw compressors have become more affordable, and their benefits are now recognized across diverse industries. Today, rotary screw air compressors are used in numerous industrial applications and are being manufactured by companies around the world, including VMAC.

Benefits

- Continuous duty cycle

- High air flow delivery

- Compact size

- No air receiver tank requires

- Few wearing parts

- Easy maintenance

Challenges

- Higher initial cost

- Requires routine maintenance

Rotary screw compressors generally have a higher initial cost when compared to the other compressor types but last longer because they have fewer wearing parts. Most screw compressors found in mobile applications are oil-injected, utilizing an independent lubrication circuit. The oil used is specific to the compressor, and the system will require routine maintenance.

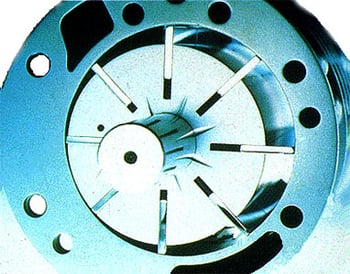

Rotary Vane Compressors

The rotary vane compressor is the least common of the three common compressor types in mobile applications. There are fewer vane compressor manufacturers than reciprocating compressor manufacturers, and service parts can be more challenging to find.

Benefits

- Fewer moving parts

- Compact

- Continuous-Duty

- Low pulsation

- Low initial cost

Like the rotary screw compressor, the rotary vane air compressor has fewer moving parts when compared to a reciprocating option. Vane compressors are compact compared to reciprocating and rotary screw compressors when comparing equal CFM compressors. They are designed for continuous duty and deliver a relatively pulsation-free air flow to your tools or equipment. The rotary vane compressor generally has a lower initial purchase cost.

Challenges

- Hard to find service parts

- Difficult to get service support

- Expensive rebuilds

As with other wearing compressors, oil carryover increases the longer it is in service. A complete rebuild is required to prevent this, which is expensive. Finding service parts and support can also be a challenge.

Choosing An Air Compressor

When choosing a compressor for your mobile application, there are many factors to consider. The initial purchase price, ease of and cost of maintenance, size, availability, airflow, and longevity are all critical for your overall satisfaction with your compressor. Knowing which compressor meets your needs is essential in finalizing your industrial compressor system decision.

Visit our OEM page to discover how VMAC can help you build your custom industrial application!