Quick Links

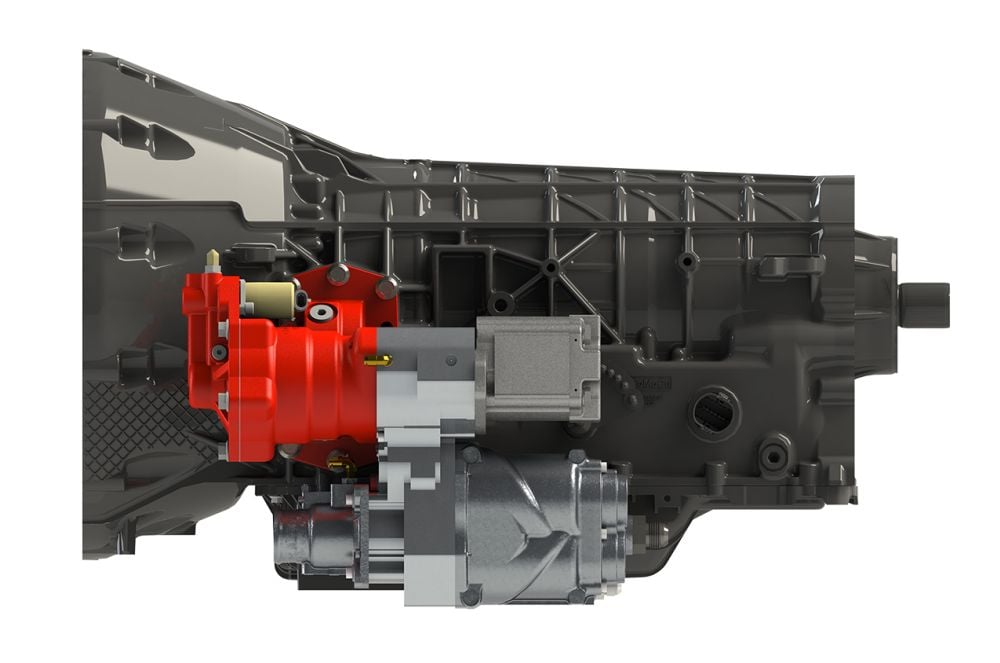

Direct-Transmission Mounted PTO Driven Multi-Power System

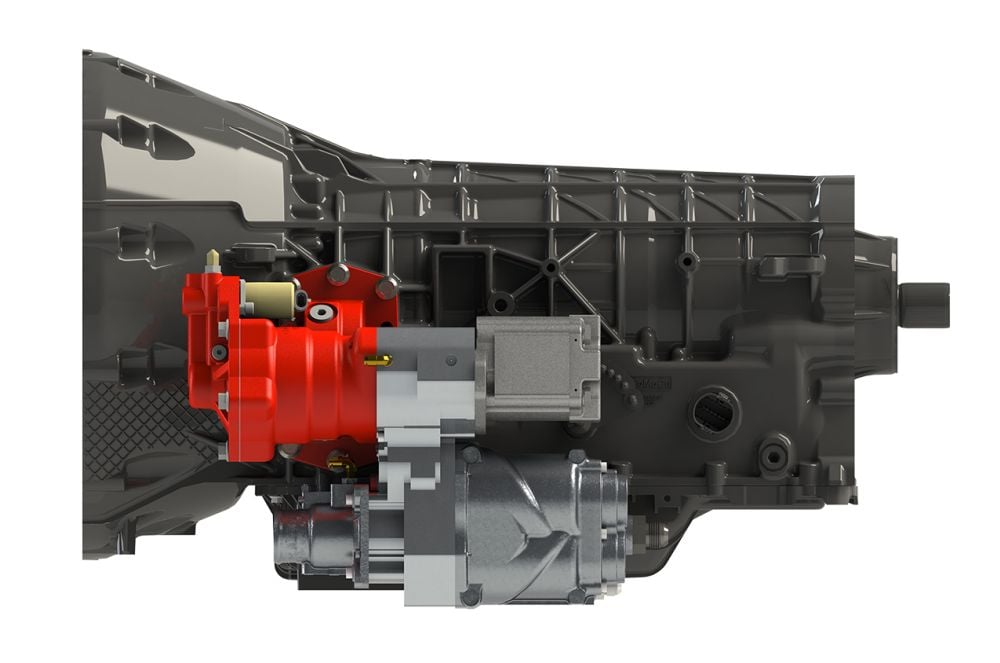

The VMAC DTM70-H multi-power system is a direct-transmission mounted PTO driven air compressor with a hydraulic pump.

The DTM70-H system is the best choice for fleet managers and owners who need to save space, reduce weight, and use air and hydraulic power at the same time. The DTM70-H multi-power system allows customers to simultaneously operate small to medium sized air tools alongside a hydraulic crane or other equipment.

Mounting kits available for:

- Ford F-250 to F-600 Power Stroke Diesel

VMAC designs truck mounting kits for the easiest possible installation. Working closely with leading truck manufacturers, VMAC ensures that mounting kits do not affect OEM warranties.

Some applications are restricted to specific series and/or models. Please confirm compatible vehicles on VMAC’s Application List.

Applications

Common jobs that use the DTM70-H multi-power system:- Commercial tire services

- Utility servicing

- Heavy equipment repair

- Sign installation

- Mechanics trucks

- Hydraulic crane trucks

- Telescopic cranes

Commonly used air tools:

- 1” impact wrenches

- 60 lb jackhammers/pavement breakers

- Backfill tampers

- Vertical/horizontal grinders

- Sanders

- OTR tire inflation

- Many other air tools/applications

Variable Air & Steady Hydraulics – One PTO

Use variable air power and steady hydraulic power at the same time with a single PTO port. The DTM70-H uses a priority valve to divert excess hydraulic flow, which allows you to get up to 65 CFM* of compressed air on demand—while simultaneously providing the consistent hydraulic power you need.

Fixed & Variable Operating Modes

The DTM70-H multi-power system allows operators to switch between fixed and variable modes, which reduces engine RPM and minimizes fuel consumption, resulting in fewer emissions and less noise on the job site. Fixed mode maintains a pre-set low engine RPM for running hydraulic equipment and provides a steady rate of compressed air. Variable mode enables engine RPM to increase and decrease automatically based on air demand, while still maintaining steady hydraulic flow. Both modes enable hydraulic equipment to operate at their required speeds.

Decrease Truck GVW By Up To 600 lb

The DTM70-H frees up truck GVW by as much as 600 lb, with no air receiver tank to mount on the truck deck and 50% smaller hydraulic tank sizes required compared to other hydraulic systems. The total system weight is only 180 lb, allowing you to add taller tool cabinets, carry more materials or equipment or take advantage of improved fuel economy while driving to the jobsite.

30% Faster Installations

The DTM70-H is application engineered for 2020+ Ford F-250 to F-600 Super Duty work trucks with 6.7 L Power Stroke diesel, and TorqShiftTM Automatic Transmission (4×4 or 4×2). No modifications are required to the Ford transfer case. No drive shafts are required, which can cause alignment issues. The system also allows for reduced hydraulic plumbing, fittings, and hoses compared to other deck-mounted hydraulic air compressors.

Free Up To 13 Cubic Feet

The DTM70-H multi-power system frees up to 13 cubic feet on the truck deck because the air compressor mounts to the transmission, and the rest of the system mounts under the truck. In fact, no components get installed on the truck deck which ensures a clean and professional looking truck, and space for other equipment, tools or materials.

Avoid Frustrating Breakdowns & Maintenance Issues

The DTM70-H air compressor is powered by a Chelsea® PTO mounted on the truck’s transmission. Because there is no secondary engine that needs constant maintenance, less time and money is spent on fixing engine issues and more time is spent on jobs making money.

Work In Any Climate

The DTM70-H multi-power system is proven to work in any extreme climate. With an integrated automatic heater, the system is ready to work when you are.

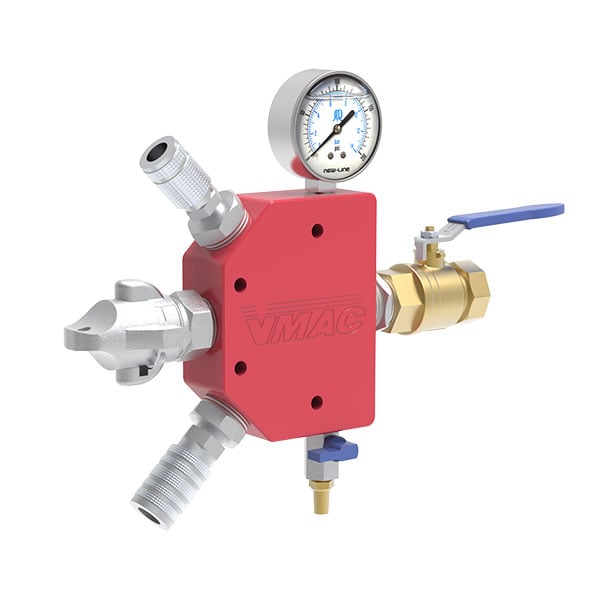

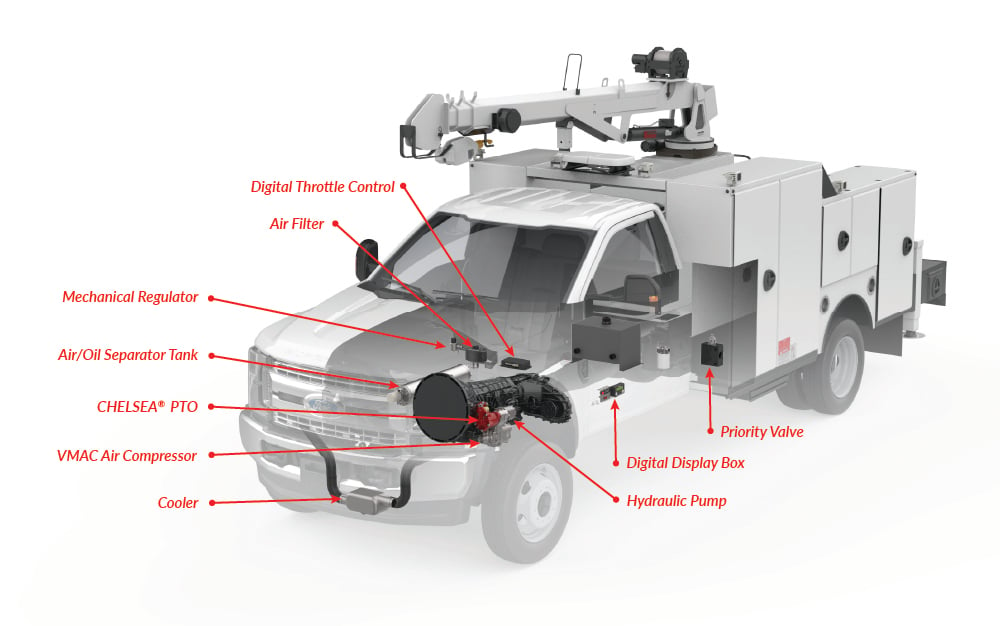

Mechanical Regulator

Easy access for setup/adjustment

Air/Oil Separator Tank

Separates compressor oil from compressed air and mounts safely to the truck’s frame rail

Digital Display Box

LCD for on/off controls; observing system status, displays error messages and stores error codes

VMAC Air Compressor

VMAC oil-injected rotary screw; up to 65 CFM* @ 100 psi; 100% duty cycle; up to 175 psi

Heater

Includes 250 W modified Sine Wave Inverter and wiring harness

Cooler

Liquid-to-liquid cooler integrates into truck’s cooling system and mounts under the truck’s radiator

Priority Valve

Diverts excess hydraulic flow to reservoir tank

PTO

Unique patented design that provides the best in class noise reduction and unprecedented torque capacity of up to 235 lb-ft, dependent on truck model year.

Hydraulic Pump

Various pump options available; 2.5 GPM-8.0 GPM; see specifications for pump options

DTM70-H Air Compressor & Hydraulics Specifications

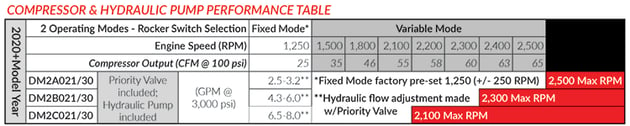

Air Compressor Output

- Up to 65 CFM* @ 100 psi (175 psi max)

- *Actual CFM output dependent on engine RPM and operating mode (see chart below)

Air Compressor Type

- PTO driven, direct-transmission mounted, 100% duty cycle, VMAC oil-injected rotary screw

Weight (wet)

-

Approximately 180 lb (81.6 kg)

PTO (included)

- Chelsea® 210 series PTO; electrically actuated, PTO indicator lamp

Hydraulic Pump Options

- 2.5 GPM-8.0 GPM*

- *Actual GPM output dependent on hydraulic pump, engine RPM, and operating mode (see chart below)

Throttle Control

- Two Operating Modes: variable and fixed; includes toggle switch to switch modes

- Fixed Mode: engine RPM stays constant at engine RPM set-point (factory pre-set 1,250, +/- 250 RPM)

Variable Mode: engine RPM increases and decreases automatically based on air demand (up to max RPM for the pump) - Both modes allow for simultaneous operation of both the air compressor and hydraulic pump

Control System

- On/off function of PTO and compressor

- Operating mode toggle switch on PTO indicator panel

- LCD display

- Service notifications

- Allows for simultaneous operation of both the air compressor and hydraulic pump

- Error messages

- System temperature

- Compatible with start/stop crane modules

Safety System

- Automatic compressor heater function

- Compressor over-temp sensor

- Automatic rapid blow-down valve on tank

- 200 psi pressure relief valve

- Truck drive disable circuit on throttle control

- Truck park brake safety shut-off switch on control box

- Priority valve diverts excess hydraulic flow to reservoir tank

Warranty

-

Two years on all major components; VMAC air-ends are covered by VMAC’s Lifetime Warranty (Limited)

-

Chelsea PTO is covered by Parker Chelsea Two Year Warranty; Chelsea pumps are covered by Parker Chelsea 18-Month Warranty

-

For details visit vmacair.com/warranty

*Actual maximum CFM and GPM output varies based on engine RPM, hydraulic pump size, and operating mode.

VMAC Direct-Transmission Mounted PTO Driven Air Compressor

Join Darren Darnley from VMAC as he shares the specs, operating modes, components, safety features, warranty, and accessories of the VMAC DTM70-H.

DTM70-H Crane Demo

Watch the VMAC DTM70-H power an IMT 7500 Telescopic Hydraulic Crane while simultaneously producing 40 CFM of air power.

PTO Air Compressor With Hydraulics - DTM70-H by VMAC

See how VMAC’s DTM70-H control system seamlessly integrates with an IMT radio remote crane control, allowing operators to easily control the crane and simultaneously run air tools.