Quick Links

UNDERHOOD® 40 Air Compressors – Truck Series

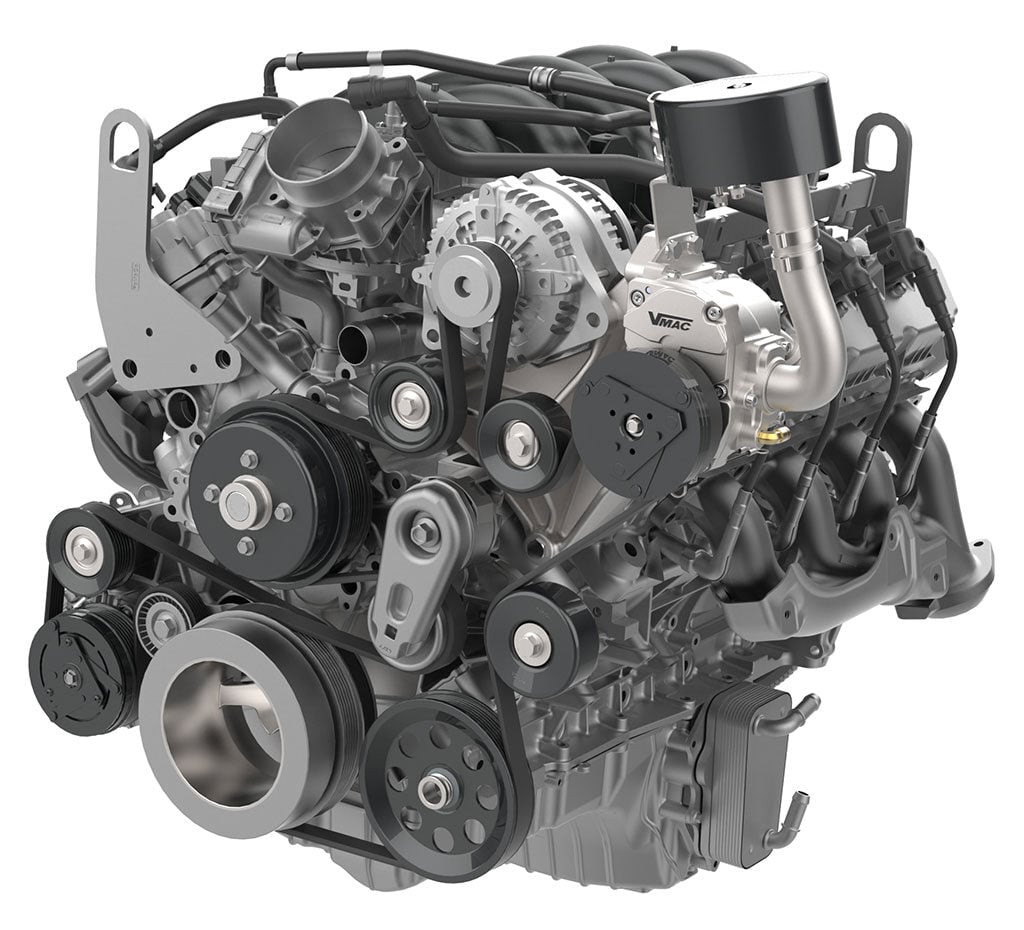

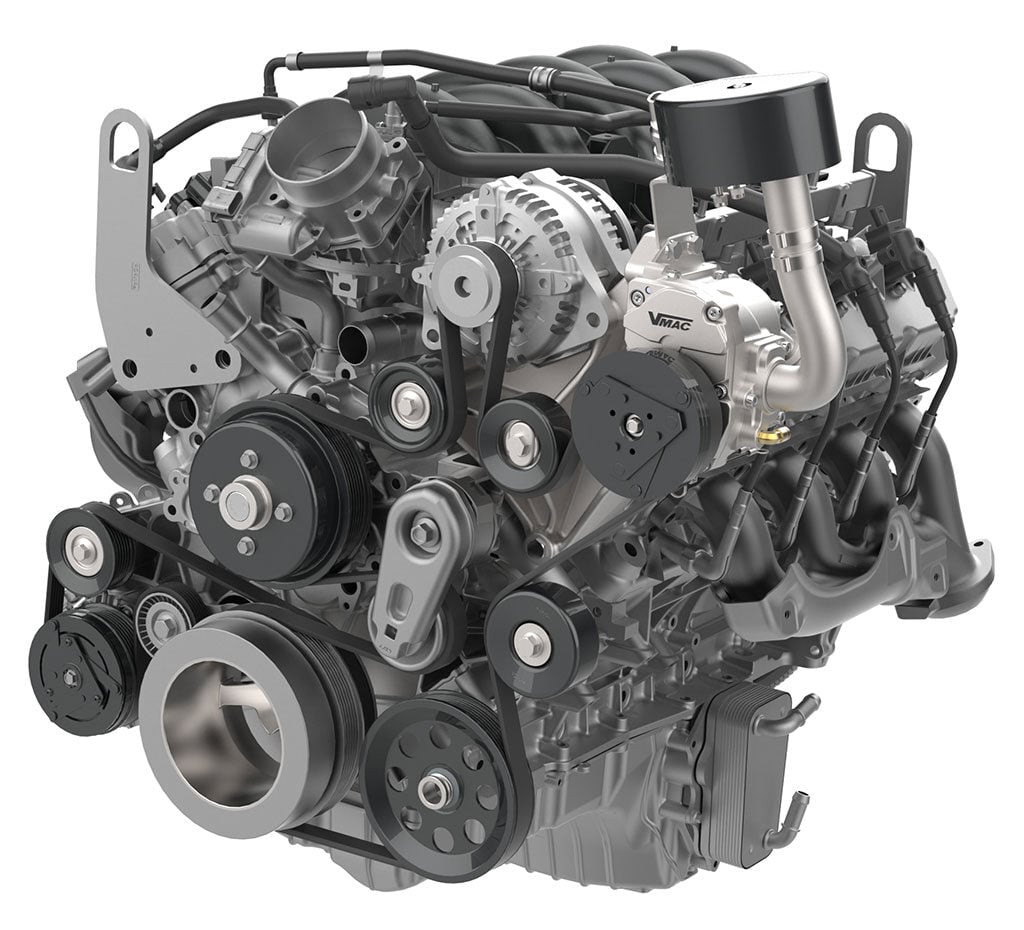

The UNDERHOOD® 40 rotary screw air compressor system is the perfect solution for service trucks and operators who use small air tools for light duty applications.

VMAC engineers truck mounting kits for the easiest possible installation. Working closely with leading truck manufacturers, VMAC ensures that mounting kits do not affect OEM warranties.

Mounting kits available for:

![]()

- Ford F-250 to F-600 Power Stroke Diesel

- Ford F-250 to F-600 Gas

- RAM 2500 to 5500 Cummins Turbo Diesel

Some applications are restricted to specific series and/or models. Please confirm compatible vehicles on VMAC’s Application List.

Applications – Common jobs that use the UNDERHOOD40 air compressor are:

- Tire servicing

- Utility servicing

- Forklift repair

Commonly used air tools – UNDERHOOD40 air compressors can be used for:

- 3/4“ impact wrenches

- Light chipping hammers

- Die grinders

- Tire inflation

Explore City of Livonia’s Smart Upgrade To UNDERHOOD® Air Compressors

“The best part was how things were engineered to fit properly in the engine compartment, as if it was built from the factory… I would highly recommend VMAC compressors to anyone with a need for portable compressed air on demand.” -Buzz Kirby, City of Livonia

Free Up To 23 Cubic Feet On Your Truck Deck

UNDERHOOD40 air compressors free up to 23 cubic feet on the truck deck or cargo area because the air compressor mounts in the engine compartment. The only space required on the truck deck or cargo area is 1.7 cubic feet for a combined air/oil cooler and air/oil separator tank.

Decrease Truck GVW By Up To 290 lb

UNDERHOOD40 air compressors reduce truck GVW by as much as 290 lb. Choosing a lightweight air compressor means you’ll be able to add more tools and equipment to your truck, carry more materials, or take advantage of better fuel economy.

Up To 40 CFM*, 100% Of The Time

UNDERHOOD40 air compressors use patented rotary screw technology designed to run at 100% duty cycle without stopping, so operators don’t have to wait for their air compressor to fill up a large air receiver tank.

Advanced Digital Controls & Telematics*

The UNDERHOOD40 with VMAC’s advanced digital controls is complete with telematics, built-in soft start, safety controls, and enhanced diagnostics. VMAC’s advanced digital controls integrate with the vehicle and provide more information about your compressor than ever before, making it easy to monitor the performance of your system and plan maintenance intervals.

* Available for most popular 2023+ model year commercial work trucks; see application list for details.

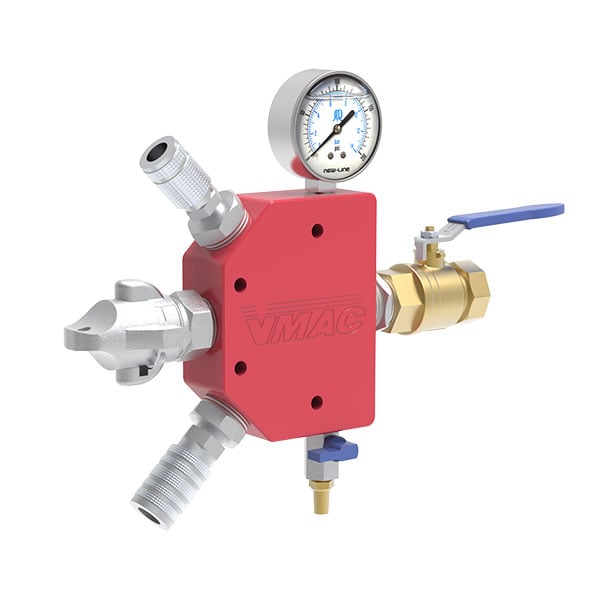

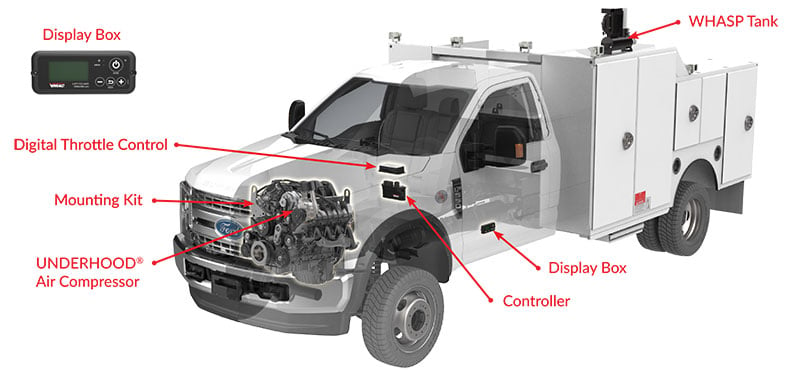

VMAC Air Compressor

Oil-injected rotary screw; up to 40 CFM* @ 100 psi; 100% duty cycle; up to 150 psi

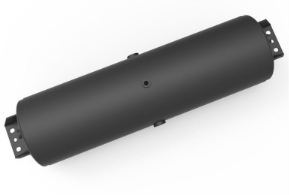

WHASP Tank

Waste Heat Air Separation Package (WHASP) Tank; an integrated cooler/tank that both cools and separates the air/oil mixture

Display Box

On/Off function of compressor; OLED displays real-time system information, service notifications & informative diagnostics messages; interface for adjusting all compressor and throttle control settings

Digital Throttle Control

Automatically modulates engine RPM depending on air usage

Control Module (Controller)

Continually monitors sensor health and safety interlocks; optional telematics provide real-time diagnostics, system use, hours, service intervals, remote start/stop, and error codes through industry standard J1939 interface

UNDERHOOD40 Air Compressor Specifications

The specifications below are for UNDERHOOD40 systems with Advanced Digital Controls. Alternatively, you can view legacy UNDERHOOD40 specifications here.

Air Compressor Output

- Up to 40 CFM* @ 100 psi (150 psi max)

Air Compressor Type

- Belt-driven, 100% duty cycle, VMAC oil-injected rotary screw

Total System Weight (wet)

- Approximately 62 lb (28 kg)

WHASP Tank

- Combined air/oil cooler, air/oil separator tank

- 19.75” (l) x 8.0” (w) x 17.5” (h); 44.5 cm (l) x 20.3 cm (w) x 50.2 cm (h)

Digital Throttle Control

- Two-speed operation

- Automatically modulates engine RPM depending on air usage

Display Box

- On/Off function of compressor

- OLED displays real-time system information, service notifications & informative diagnostics messages

- Interface for adjusting all compressor and throttle control settings

Control Module (Controller)

- Continually monitors sensor health and safety interlocks

- Optional telematics provide real-time diagnostics, system use, hours, service intervals, remote start/stop, and error codes through industry standard J1939 interface

Safety System

- Automatic system checks prior to engaging compressor

- Compressor temperature, pressure & blowdown sensors

- Compressor thermal protection circuit

- Open/short circuit real-time diagnostics on sensors

- Automatic rapid blow-down valve & 200 psi air pressure relief valve on WHASP tank

Air Receiver Tank (required, not included)

- Minimum 6-gallon air receiver tank required for best performance

Warranty

- Two years on all major components; VMAC air-ends are covered by VMAC’s Lifetime Warranty (Limited); for details, visit www.vmacair.com/warranty

*Actual maximum CFM output of the air compressor varies by vehicle application. See Application List for details.

Advanced Digital Controls & Telematics available for most popular 2023+ model year commercial work trucks.

UNDERHOOD® 40 Air Compressor by VMAC - The Real User Experience

See the UNDERHOOD® 40 Vehicle Mounted Air compressor performing standard service call tasks. Come along for the ride and watch this real user experience from a first person view.

Tour The VMAC Demo Truck With Tim Parks

Allow Tim Parks from VMAC to take you on a tour of his VMAC demo truck, loaded with VMAC’s rotary screw air compressors and multipower systems. Tim will also focus on the UNDERHOOD® 40 air compressor system, the only air compressor that fits in the engine compartment of trucks and vans.