Quick Links

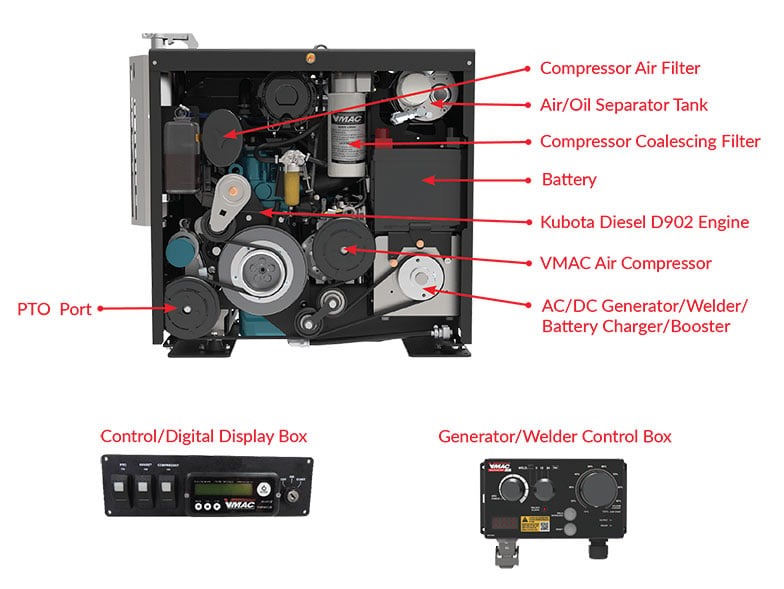

Components included:

- 45 CFM Rotary Screw Air Compressor

- 8 kW AC Generator

- 250 A DC Welder (adjustable)

- 300 A max @ 13V Booster (adjustable)

- 100 A max @ 12V, 24V Battery Charger (adjustable)

- Factory-installed Cold Climate Kit – 120V, tested to -40°F (-40°C)

- Optional 2,800 RPM Power Take-off Port

- Optional 5 GPM, 8 GPM or 10 GPM @ 3,500 psi (max) Hydraulic Pump

Applications – Common jobs that use 6-in-1 Power Systems:

- Mobile heavy duty mechanics

- Heavy equipment repair technicians

- Remote access jobs in mining, logging, and oil & gas

Discover Stahl Peterbilt’s New Standard With The VMAC Multifunction

“The VMAC offers better performance and better productivity… Part of our success is due to our equipment, and Peterbilt is looking at the VMAC Multifunction as the benchmark for service truck business.” -Randy Kerry, Stahl Peterbilt

Free Up Space

VMAC Multifunction Power Systems leave more space on your truck deck or cargo area because they combine multiple functions into one compact system. The overall system size is six cubic feet smaller than other leading multi-power brands and designed to fit on the side pack of a service truck with a slider.

Reduce Weight

VMAC’s Multifunction reduces truck GVW by 400 lb. Choosing a lightweight multi-power system means you’ll be able to add more tools and equipment to your truck, carry more materials, take advantage of better fuel economy, or even downsize your truck classification.

Reduce Truck Maintenance & Fuel Costs

Multifunction Power Systems save truck maintenance costs and improve fuel economy by allowing you to turn your truck engine off while on the job site. The control system not only automatically idles the system’s engine up/down with air demand, it also turns the engine off/on with air demand.

Easy To Operate & Switch Between Systems

VMAC Multifunction Power Systems allow you to seamlessly switch between operations, without the hassle of complicated controls or maneuvering multiple machines on the job site. This means more time working, improving productivity, and getting your customers back to work faster. It is designed for ease-of-use, to run efficiently with only one operator.

Improve Safety With Noise Reduction Technology

With noise reduction panels, low and high idle controls, and Standby Mode, operators can safely communicate while working without disturbing the job site or neighbors.

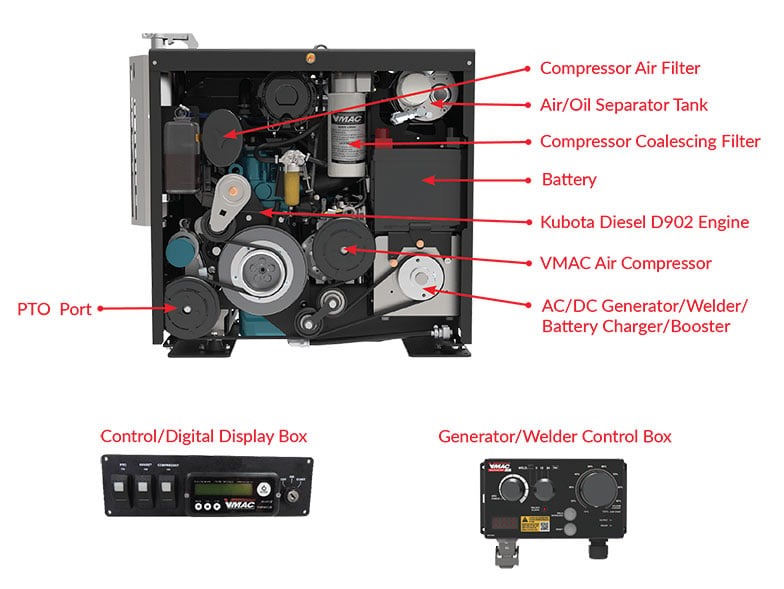

Air Compressor

Oil-injected rotary screw; belt-driven; 45 CFM @ 100 psi; 100% duty cycle; up to 175 psi

AC/DC Generator/Welder/Battery Charger/Booster

- AC: 8 Kw output (w/ receptacles)

- 1 x 30 A, 240V, 60 Hz three phase circuit

- 1 x 30 A, 240V, 60 Hz single phase circuit

- 2 x 20 A, 120V, 60 Hz single phase circuit

- DC: For battery boosting/charging; other DC loads

- Boost – 300 A max @ 13V; Charge – 100 A max @ 12V, 24V

- CC mode for SMAW and GTAW (stick/TIG welding)

- 250 A @ 35% duty cycle; 190 A @ 60% duty cycle

Generator/Welder Control Box

GENSET voltage meter & selector; welding current control and ARC force; socket for optional remote welding control

Kubota D902 Diesel Engine

Tier 4 Final; 3-cylinder, naturally aspirated 3,600 RPM

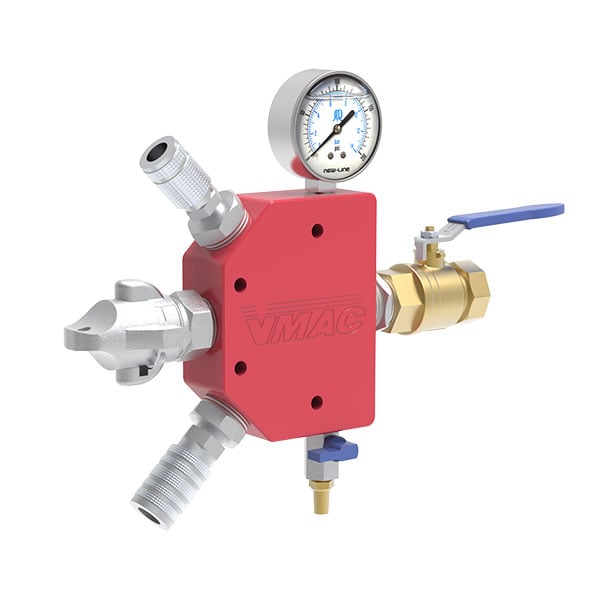

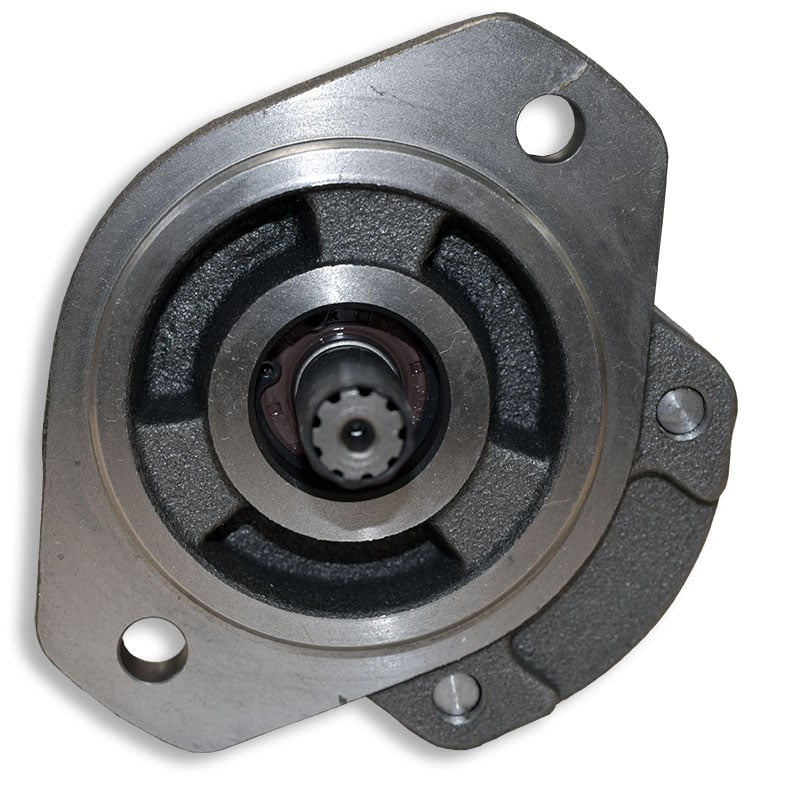

PTO Port (Optional)

Clutched SAE ‘A’ port with 9-toothed spline, 2,800 RPM output, 35 lb-ft continuous torque max (patented)

Control/Digital Display Box

Remote mounted; electronic key switch; selector switches for PTO/GENSET/COMPRESSOR; LCD for compressor on/off controls, observing system status and adjusting parameters

Air/Oil Separator Tank

Separates compressor oil from compressed air

Battery

Included ACDelco 12V, 460 CCA, 575 CA

Cold Climate Kit For -40º

Cold Climate Kit is recommended if ambient temperatures frequently drop below -10ºC (14ºF); combine with an optional 1,750 W inverter to warm the system on the way to the job site

6-in-1 Power System - Kubota Specifications

Air Compressor

- 45 CFM @ 100 psi (175 psi max)

- VMAC oil-injected rotary screw; 100% duty cycle; belt-driven

Engine

- Kubota D902 Diesel 3-cylinder, naturally aspirated 3,600 RPM, Tier 4 Final

Weight (wet)

- Approximately 570 lb (259 kg)

Dimensions

- 33” (l) x 23” (w)* x 29” (h); 83.8cm (l) x 58.4 cm (w)* x 73.7 cm (h);

- Base footprint: 30” (l) x 20” (w); 76.2 cm (l) x

- *27” (68.6 cm) w/ radiator sound deflector

Decibels (dB) @ 21 feet (6.4 meters)

- 75 dB at max idle, 66 dB at low idle, 0 dB in standby mode

AC/DC Generator/Welder

- AC: 8 kW output (w/ receptacles)

- 1 x 30 A, 240V, 60 Hz three phase circuit

- 1 x 30 A, 240V, 60 Hz single phase circuit

- 2 x 20 A, 120V, 60 Hz single phase circuit

- DC: For battery boosting/charging; other DC loads

- Boost – 300 A max @ 13V; Charge – 100 A max @ 12V & 24V

- CC mode for SMAW and GTAW (stick/TIG welding)

- 250 A @ 35% duty cycle; 190 A @ 60% duty cycle

Power Take-off Port (optional)

- Clutched SAE ‘A’ port with 9-toothed spline, 2,800 RPM output, 35 lb-ft continuous torque max (patented)

Hydraulic Pump (optional)

- 5 GPM, 8 GPM or 10 GPM @ 3,500 psi (max)

Battery

- ACDelco 12V, 460 CCA, 575 CA

Control System

- Remote mounted control/digital display box with electronic key switch and LCD for compressor on/off controls, observing system status, and adjusting parameters

- Remote mounted generator/welder control box with genset voltage meter and selector, welding current and ARC force control

- Socket for optional remote welding control

- Integrated voltage sensing interlock feature ensures safe welding/battery boosting and protects equipment by disabling the genset in unsafe conditions

- Separate selector switches engage compressor, generator and PTO; any function or all three can be selected at any time

- Multi-speed throttle control responds to operating function and air demand

- With compressor-only selected, and sustained periods of no air use, the control system will shut down the engine (standby mode); the engine will not shut down automatically with generator selected

Cold Climate Protection

- Engine and compressor wait until the system temperatures are above 41°F (5°C) before loading and going into a running state

- Engine automatically restarts when system temperature falls below 23°F (-5°C)

- Small heat strip included in LCD Digital Control Box

- Battery jump start connections are recommended to be tied into the truck batteries in locations where extreme cold is expected. It is not necessary in mild climates

Cold Climate Kit

- Recommended to use if ambient temperatures frequently drop below -10ºC (14ºF)

- Plugs into a 120V power source and the compressor and separator tank heaters will turn on

- Optional 1,750 W power inverter allows cold climate kit to engage on the way to the job site

Fuel Supply Options

- 7-gallon tank with fuel gauge and low fuel shut-off sensor

- External Diesel Fuel Pump Kit

Air Receiver Tank

- Minimum 10-gallon air receiver tank recommended (not included) for proper operation of all functions

Warranty

- Two years on all major components; VMAC air ends are covered by VMAC’s Lifetime Warranty (Limited)

- Kubota engine covered by Kubota’s 2-Year warranty

- For more information about warranty policies, visit www.vmacair.com/warranty