OEM Air Compressor Applications

VMAC has over 25 years of experience working with equipment manufacturers, designing custom OEM rotary screw air compressors for a variety of challenging applications. From air brakes to spray foam systems, railway maintenance to air arc welding, VMAC OEM solutions offer air compressor systems with air output ranging from 15-150 CFM at 100% duty cycle.

VMAC’sOEM Applications

VMAC’s specialty is to custom design compact, lightweight and powerful rotary screw air compressor systems for your industrial applications with annual volume sales of 100+ units. We’re here to help you sell more units for your niche market and provide your customers with a reliable compressed air solution.

Browse the list of applications below for examples of customer solutions developed by VMAC’s OEM team.

Electric Air Brakes

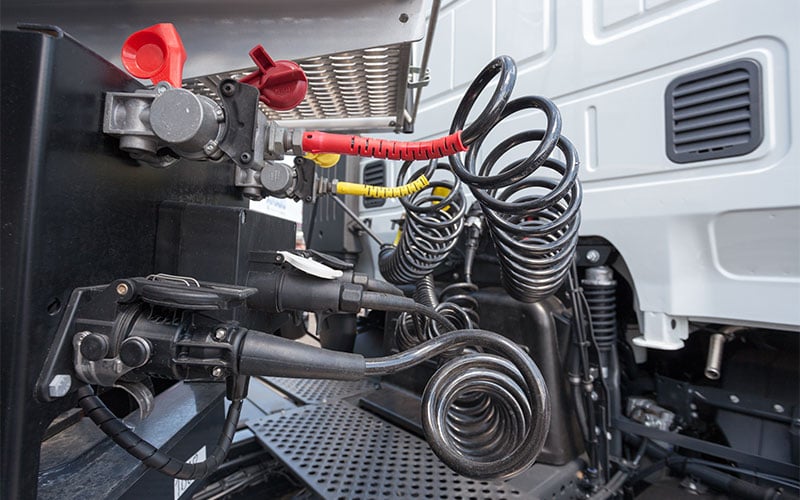

VMAC designs the most reliable 10-20 CFM electric air brake compressors for transit buses, school buses, and Class 8 trucks.

Air Brakes

Better suited for high-duty cycle usage, VMAC offers a rotary screw air compressor solution for your demanding air brake needs.

Spray Foam

Portable, lightweight spray foam systems available for many applications. Adding an onboard air compressor rather than towing one to the job site reduces the need for another vehicle or a second trip.

Pothole/Crack Sealing

Turn your pothole/crack sealing trailer into an all-in-one package. Adding an air compressor to your existing engine provides you with added value and reduces the need for additional pieces of equipment.

Air Arc Gouging

When the job calls for structural steel welding and other rugged outdoor work, you need an engine-driven welder that covers all your process needs – stick, MIG, TIG, flux-cored and gouging. Upgraded for reduced emissions, the Lincoln Air Vantage series has been re-engineered to deliver smoother arc characteristics and improved pipe welding capabilities. The Lincoln Air Vantage® 566X includes a VMAC belt-driven compressor with separate gauges to monitor compressor hours and pressure.

Air Tools

Sometimes you just need air to power traditional pneumatic tools, blow off your equipment or fill a tire. Give yourself that option by including a rotary screw air compressor with your equipment or machine.

Railway Maintenance

Railway maintenance is tough enough without having to manage extra pieces of equipment. Use an existing unit to power your air compressor by adding a rotary screw compressor system to it.

Railcar Movers

Railcar movers are a practical, convenient way to move rail cars around—if you have the right equipment to keep up with the high air demand. Rotary screw air compressors are powerful, compact, and require less maintenance than other compressor options.

Compressed Air Foam Firefighting Equipment

Mobile compressed air foam firefighting requires vehicles that can quickly reach the scene. Adding a lightweight, powerful rotary screw compressor to your CAF system’s engine provides a compact unit ready to go when duty calls.

Dust Extraction

Maximize performance with dust extraction tools that are more powerful without increasing the size or space required. With a 100% duty-cycle VMAC rotary screw compressor as part of your equipment, wait times will be a thing of the past and you can operate your filtration system at peak capacity in even the most demanding environments.

Compressor/Generator

Many applications have a diesel engine driven generator supplying power to their equipment, while at the same time supplying power to run an electrically driven air compressor, on the same application. Instead of powering the electric motor driven compressor with the generator, why not use the diesel engine to power both the generator and the air compressor at the same time and save a step. One driver instead of two.

Water Blasting/Water Jet Cutting

Water blasting systems need powerful compressors for efficient, cost-effective cleaning. VMAC’s compressors can power systems at different pressures, allowing OEMs to build innovative water blasting and water jet cutting technology.

Water Pump Primers

VMAC compressors are compact, powerful and reliable, helping you ensure your water pump will operate when needed, for as long as you need, and can be counted on to perform for the lifespan of the equipment.

Carpet & Duct Cleaning

Every pound and inch counts when operators are hauling carpet and duct cleaning equipment around. Rotary screw compressors offer a lightweight and compact power solution allowing operators to complete jobs faster than ever before.