Why Does My Air Compressor Perform Differently At High Altitudes?

Anyone who has used an air compressor at high altitudes knows how frustrating it can be. At higher altitudes, air compressor performance is degraded, and it can take a lot longer to complete tasks than at lower altitudes. People who move to or work in areas that are at a higher altitude are often surprised when their air compressor seems to be working slower than normal. Why does this happen? Let’s break it down…

How an Air Compressor System Works

Most mobile air compressor systems have a gas or diesel engine that powers the air compressor. When you turn this engine on, the air compressor system draws in ambient air through the compressor intake and then compresses that air to a smaller volume. The compression process forces air molecules closer together, increasing their pressure. This pressurized, compressed air can then be stored in a storage tank or used to directly power your tools and equipment.

You can learn more about this in our Top 10 FAQs about Compressed Air, if desired.

Air Density & Atmospheric Pressure

The ambient air around us is made up of many molecules of different gases, which typically includes 78% Nitrogen, 20-21% Oxygen, and 1-2% water vapor, carbon dioxide, and other miscellaneous gases. The amount of these molecules in a given volume is referred to as the density, or air density in the context of air. Air density is directly impacted by atmospheric pressure.

As altitude increases, the atmospheric pressure decreases. Atmospheric pressure is caused by the weight of all the air molecules above you pressing down and compressing the air around you. At higher altitudes, there is less air above you, and therefore less weight, which results in a lower atmospheric pressure.

How Does This Affect Air Compressor Performance?

At elevated altitudes, lower atmospheric pressure means that the air molecules are less tightly packed together and have lower density.

When an air compressor draws in air as part of its intake process, it draws a fixed volume of air. If the air density is lower, fewer air molecules are drawn in with this air into the compressor. This results in a smaller volume of compressed air and less air is delivered to the receiver tank and tools during each compression cycle.

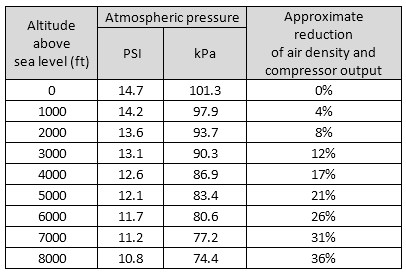

You can see the effects of altitude on air compressor performance in this table:

Engine Power Reduction

Another factor to consider is the effect of altitude and air density on the operation of the engine that is powering the compressor.

As altitude increases, the air density decreases, which results in a roughly proportional decrease in the horsepower your engine is able to produce. For example, a normally aspirated diesel engine might have 10% less power available at 800 m/2600 ft and 20% at 1600 m/5200 ft, when compared to operation at sea level.

Reduced engine power can result in a situation where the engine bogs down and the RPM drops which results in fewer compression cycles per minute and therefore less compressed air output. In extreme cases, the engine may not be able to run the compressor at all and will stall.

Different engines will have different de-rate curves depending on the engine design, and some turbocharged engines can compensate for the effects of altitude. If you are working or plan on working at higher elevations, it is recommended to consult your specific air compressor engine manufacturer to determine the impacts of elevation on your air compressor.

How To Overcome Altitude-Related Problems

There are a few ways of potentially overcoming the challenges of using your air compressor at high altitudes.

In some cases, a simple adjustment of engine RPM to increase the compressor speed will be all that is required. Or, if the compressor is belt driven, it may be possible to change pulley diameters to increase the operating speeds of the compressor without changing the engine speed.

Some engine manufactures may also have high altitude components or programming to help offset the power decrease. Using a higher output engine and compressor system that has enough power and CFM to meet your needs even with the performance drop might be a viable option as well.

If you’re having challenges with air compressor performance at higher altitudes, consult the air compressor manufacturer to see what they can offer.

Learn more about air compressors

- Top 10 FAQs & Fun Facts About Compressed Air

- Keeping Your Cool: Managing The Heat Rejection Requirement of Your Air Compressor Systems

- VMAC Product Finder – Discover The Best Air Compressor For Your Needs