Air Compressors For Mobile Mechanics

Mobile mechanics are critical for many industries, keeping machinery working and moving. These Red Seal professionals often specialize in heavy duty mechanics, servicing vehicles and machines in remote locations that can be difficult to reach. Every second of downtime can be costly, and mobile mechanics need to work quickly and efficiently at every job site.

Mobile mechanics are critical for many industries, keeping machinery working and moving. These Red Seal professionals often specialize in heavy duty mechanics, servicing vehicles and machines in remote locations that can be difficult to reach. Every second of downtime can be costly, and mobile mechanics need to work quickly and efficiently at every job site.

Choosing optimal equipment, including the best air compressor for the work being done, helps mobile mechanics reach their goals faster. Mobile mechanics use air compressors to power pneumatic tools, including impact wrenches, to blow out radiators, and to inflate tires.

Air Compressors Made For Mobile Mechanics

Most air compressors built today are not meant to move. Instead, they are stationary air compressors built for shops and other indoor settings. While they perform well, they were never built for the rugged demands of mobile work and should not be used by mobile mechanics.

Fortunately, a select few manufacturers specialize in making air compressors just for service trucks. These air compressors are built for mobile mechanics; they can endure the weather, altitude changes, vibrations, changing vehicle angles, and wear and tear that comes along with tough mobile mechanic work.

Fortunately, a select few manufacturers specialize in making air compressors just for service trucks. These air compressors are built for mobile mechanics; they can endure the weather, altitude changes, vibrations, changing vehicle angles, and wear and tear that comes along with tough mobile mechanic work.

Mobile air compressors designed for mechanics are powerful yet often smaller and lighter than stationary compressors, providing numerous additional benefits. Mobile and field mechanics who choose a mobile air compressor can benefit from reduced GVW, extra space for other equipment and tools, and a better-looking service vehicle.

Rotary Screw vs. Reciprocating Air Compressors

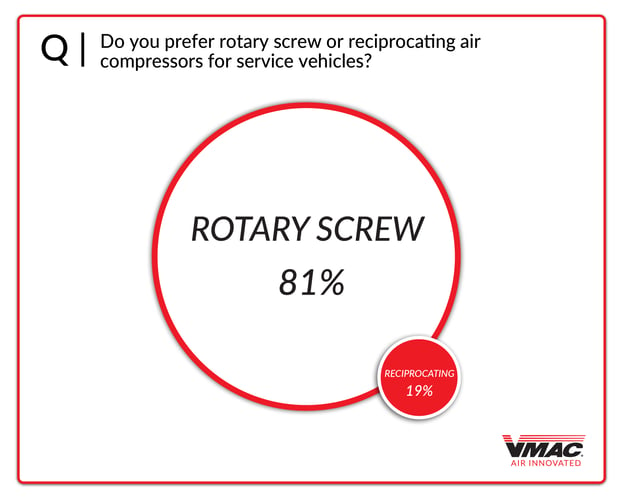

There are two primary categories for mobile air compressors: rotary screw and reciprocating. Both have their advantages and disadvantages, but rotary screw air compressors almost always come out on top.

In 2023, VMAC surveyed 331 mobile air professionals and asked whether they preferred rotary screw or reciprocating air compressors for their service vehicles. The results strongly favor rotary screw air compressors, with 81% choosing rotary screw air compressors over reciprocating.

When asked why they preferred rotary screw air compressors, the mobile mechanics gave the following reasons:

- Performance

- Quality / Reliability

- Size / Weight

Performance

Rotary screw air compressors are known for superior performance over other air compressor types. Because of the way these air compressors are designed, rotary screw air compressors operate at 100% duty cycle. There is no need to wait for an air receiver tank to fill, as these air compressors are always ready to provide their full CFM load on demand.

Size/Weight

Despite their incredible performance advantages, rotary screw air compressors are also smaller and lighter than reciprocating air compressors, which means they take up less space on the truck and can free up weight for other tools and equipment.

Quality/Reliability

Last but not least, rotary screw air compressors are highly reliable. As long as routine maintenance is performed, rotary screw air compressors can easily outlive the life of the service truck they are mounted on. This reliability makes them a highly desirable option for mobile mechanics who rely on their equipment to get their jobs done.

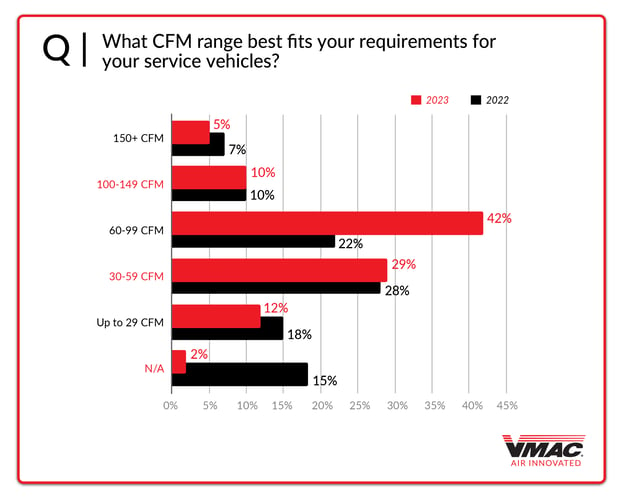

How Much CFM Do Mobile Mechanics Need?

Most mobile field mechanics need between 30-100 CFM to power their tools and perform their work, with most requiring 60-99 CFM. In some cases, mobile mechanics may require up to 149 CFM, but very rarely require more.

To determine CFM needs, consider the exact tools that will be used. For example, a ¾” impact wrench needs approximately 30-40 CFM, while a larger 1” impact wrench tends to require 60-70 CFM. Higher CFM is often only needed for larger tools, such as a jackhammer, or specialized equipment.

Mobile mechanics can check their tool specs for CFM requirements and then let those requirements dictate the CFM requirement of their air compressor.

The Best Air Compressors For Mobile Mechanics

We’ve already determined that mobile design, rotary screw, and CFM requirements are critical considerations when choosing an air compressor for mobile mechanics. But how do you find the best air compressor on the market today?

The final step is to determine the ideal power source and select an air compressor that matches that power source. The first two options outlined below are sophisticated vehicle-integrated solutions for those who love cool technology, followed by simpler, tried-and-true vehicle mounted air compressor options.

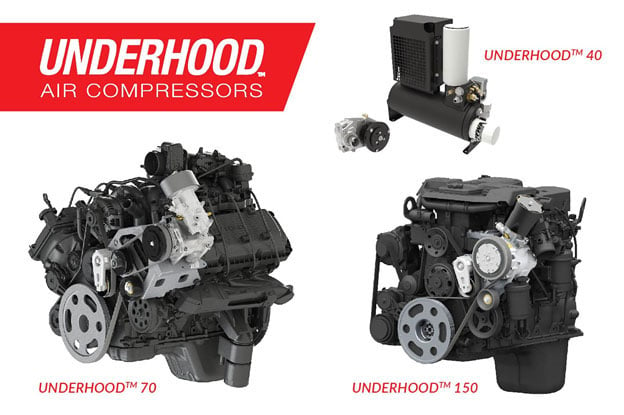

UNDERHOOD Air Compressors

UNDERHOOD air compressors are highly innovative air compressors exclusively designed by VMAC due to their sophisticated engineering and manufacturing requirements. UNDERHOOD air compressors mount within the vehicle's engine compartment and use belt drives to draw power from the engine.

UNDERHOOD air compressors are some of the most compact and powerful mobile air compressors on the market today, and models can produce up to 40, 70, and 110 CFM.

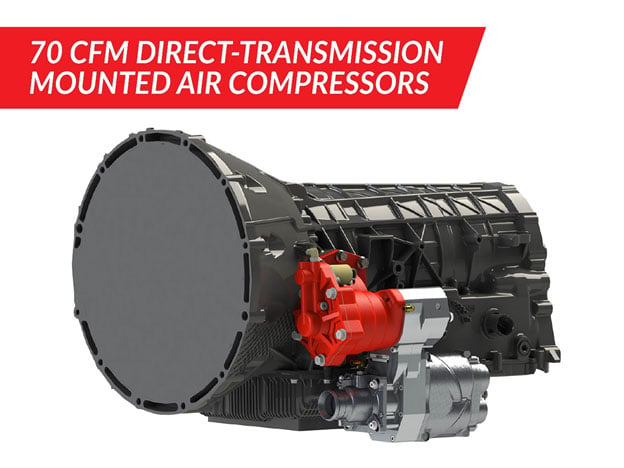

Direct-Transmission Mounted Air Compressors

Another VMAC exclusive, Direct-Transmission Mounted air compressors are mounted, you guessed it, directly on the transmission. These 70 CFM air compressors use the vehicle’s existing PTO port to power the system and are another highly compact and powerful mobile air option.

The DTM is also available in a DTM70-H model, which provides air power for pneumatic tools and hydraulic power for service truck cranes. Mobile mechanics can use the DTM70-H to operate their hydraulic system and air power system simultaneously, which allows for efficient multitasking on the job site.

Check out the DTM70 and DTM70-H here.

Hydraulic Air Compressors

Hydraulic air compressors are one of the most popular mobile air compressor options, and VMAC’s hydraulic systems offer 25-60 CFM. These air compressors are a great choice for service trucks with hydraulic power, as they integrate seamlessly into the vehicle’s existing hydraulic system.

Hydraulic air compressors are proven to be powerful, sturdy, and reliable, with minimal servicing and maintenance needs. They work well in every climate and offer a drama-free option for mechanics who want a simple, straightforward solution.

Learn more about VMAC’s innovative hydraulic air compressor here.

Gas Driven Air Compressors

Gas driven air compressors are another solid option for field mechanics with lower CFM needs or mechanics who are happy to have a small air receiver tank, which can temporarily increase air power. For example, a 30 CFM rotary screw gas driven air compressor can handle up to ¾” impact wrenches, and up to 1” with an air receiver tank.

Gas driven air compressors have the additional benefit of being the most affordable rotary screw option on the market. Mobile mechanics who want the capabilities and space and weight reductions of a rotary screw compressor, but are on a tighter budget, are well suited for this air compressor.

Gas driven air compressors with generators are also rising in popularity. These convenient machines combine two forms of power—air power and electric power—in a single system. They are a great option for mobile mechanics who like to switch between air and AC power.