Considerations Of Auxiliary Port Driven Air Compressor Systems

Many industrial engines come equipped with an auxiliary port (pump drive) to power accessory equipment. Typically, hydraulic pumps or standard piston-type air compressors are mounted to this port, but they aren't the only options. For jobs with high-duty cycles and significant airflow needs—such as spray foam, pump priming, air gouging, and dust collection—rotary screw air compressors often outperform conventional solutions.

VMAC's OEM division offers direct-drive, port-mounted rotary screw compressors tailored for unique applications. However, before mounting one to an auxiliary port, several critical considerations must be evaluated.

1. Power Requirements

The required horsepower (HP) per cubic feet per minute (CFM), thermal efficiency of the compressor, and other engine loads will dictate the engine size. Manufacturers provide power output ratings for the auxiliary port, but consider additional equipment demands on the engine. Matching the engine's power and RPM curves to all connected equipment is vital for optimal performance. Learn more in our article on power requirements for industrial engine powered air compressors.

2. Torque Pulses

Torque pulses result from the engine's firing order, cylinder count, and compression ratios, especially in diesel engines. These pulses can significantly impact component performance. High-strength materials and precision engineering help mitigate the impact of torque pulses, ensuring reliable operation. Lovejoy Inc.’s article on diesel vibration provides valuable insights.

3. Port Limitations

Auxiliary ports have specific torque (ft-lb) and load ratings, which vary depending on the equipment. Smooth, low-load devices like blowers put less stress on the port, whereas heavier-loaded rotary screw or piston compressors exert greater demands. Inside the port, the gear train is designed to transmit power and handle the load of the equipment attached. Consulting with both engine and compressor manufacturers ensures compatibility and prevents overloading.

4. Output vs. Engine RPM

Rotary screw compressors deliver air (CFM) in ratio to the speed of the rotors. The more rotor rpm, the more air delivered. Compressor gearing can help deliver more air at lower engine speeds. When coupling a compressor to the auxiliary engine port, the port gearing also affects the speed at which the engine is required to run. Some ports have 1:1 gearing, while others are designed as a speed increaser. Knowing the air requirements of the job and the engine speed, port gear ratio, compressor gearing, and compressor displacement will determine which compressor is required.

5. Direction Of Rotation

Auxiliary ports may rotate clockwise or counterclockwise, depending on the engine make, model, and configuration. As rotary screw compressors are designed for a specific rotational direction, mismatched setups can lead to rapid mechanical failures.

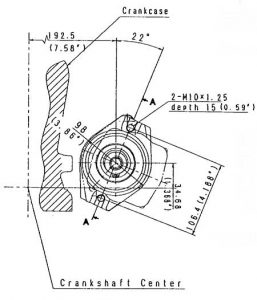

6.  Space Constraints & Clearances

Space Constraints & Clearances

Engine components, mounts, casting features and the location of the engine port will determine how much space is available to mount a component to the engine port. The size and shape of that component is also critical. Some components have mounting flanges that can be rotated to increase the options for mounting. Ultimately, mounting the component to the engine, either in CAD or in reality, will determine fitment.

7. Port & Input Shaft Compatibility

Most auxiliary engine ports are manufactured to an SAE standard. SAE A, SAE B, and SAE C ports are all common in North America. In Europe, DIN ports are standard. Input shafts generally have a few options: tapered shafts, keyway shafts and spline shafts are common. The auxiliary component must match both the port and shaft type for it to fit.

8. Overhung Load

Port specifications include how much load the port will support without needing a brace to mount the auxiliary component. If using a gear on the compressor to interface with the gear train in the port, an overhung load can cause issues. Longer components are also likely to vibrate.

Unsupported radial and axial overhung loads may cause failures to your equipment. The Gates Corporation defines overhung load as a force exerted perpendicular to a shaft beyond the outermost bearing. When that force exceeds the maximum rated capacity for the equipment, shafts and bearings become overloaded and wear out at a higher-than-normal rate. Although the article references belt driven components, the theory also applies to port drives.

9. Cooling Requirements

Effective cooling is critical for both engine and compressor longevity. Consider whether your setup integrates the engine's cooling system or uses an independent solution. Our guide on managing heat rejection requirements, covers this topic in depth.

10. Air Intake Placement

Mounting a compressor tight to the engine can optimize the available space, however, it can also introduce the challenge of ensuring your intake air is cool. To maximize efficiency and minimize wear, route the air intake away from heat sources like exhaust systems and position it to draw cooler, cleaner air from outside enclosures. High-quality intake filtration further protects the system from contaminants.

11. Operating Temperatures

Ambient and operating temperatures affect compressor performance and durability. Select equipment designed to operate within the expected temperature range to ensure consistent airflow and longevity. Learn how inlet temperature impacts airflow in our detailed analysis.

Conclusion

Auxiliary port-driven rotary screw air compressors provide a practical solution for various demanding applications. By considering power requirements, compatibility, and environmental factors, you can integrate a reliable, high-performance system. Always consult with manufacturers to verify equipment compatibility and optimize system performance.