What Is A Hydraulic Air Compressor?

A hydraulic air compressor is an air compressor powered by the hydraulics on a vehicle or machine. It allows operators to convert their hydraulic power into air power, ultimately equipping a vehicle or machine with both hydraulic and air power.

A hydraulic air compressor is an air compressor powered by the hydraulics on a vehicle or machine. It allows operators to convert their hydraulic power into air power, ultimately equipping a vehicle or machine with both hydraulic and air power.

How Does A Hydraulic Air Compressor Work?

A hydraulic air compressor converts hydraulic power into mechanical power, and then mechanical power into air power.

To convert hydraulic into mechanical power, a hydraulic pump pushes hydraulic fluid into a hydraulic motor, forcing it to spin. This spinning motor connects to an air compressor using a belt or direct drive, which powers the air compressor system and converts mechanical power into air power.

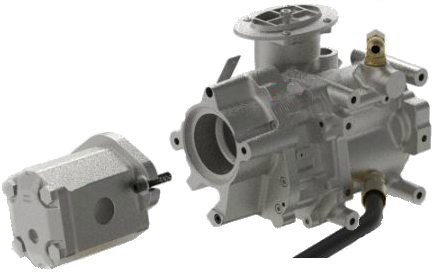

Figure 1: A hydraulic motor (left) and direct-drive air compressor by VMAC

Please note this is a simplified explanation, as numerous other components may or may not be required, including manifolds, hoses, valves, cooling systems, etc.

Regardless of the exact configuration, the core components of any hydraulic air compressor setup include:

- Hydraulic Pump – pushes hydraulic fluid through the system

- Manifold – controls the flow of hydraulic fluid to the motor

- Hydraulic Motor – forced to rotate by the hydraulic fluid

- Air Compressor – powered by the hydraulic motor

- Cooler/Reservoir – hydraulic fluid returns from the motor to the cooler, then reservoir tank

These components work together to transform hydraulic power into air power.

What Are The Benefits of a Hydraulic Air Compressor?

Hydraulic air compressors have many benefits, including the ability to run air tools. Air or pneumatic tools are highly powerful tools that enable operators to perform tasks quickly and efficiently.

Common Tools Powered By Hydraulic Air Compressors

Hydraulic air compressors can power a wide variety of air tools across numerous applications. Some of the most common pneumatic tools used with hydraulic air compressors are:

- Impact wrenches

- Jackhammers

- Air chucks

- Grinders

- Chipping hammers

- Air spades

- Moles

- Post pounders

More Hydraulic Air Compressor Benefits

While many air compressors enable operators to use air tools, hydraulic air compressors have additional benefits that make them a great choice for many operators:

- Easy access to both hydraulic and air power

- Integrates with existing power source

- No need for a new, separate compressor engine

- Cost-effective compared to other vehicle-integrated air compressors

- Relatively easy to install & use

- Safe & reliable

- Transferable between vehicles with similar hydraulics

When Should I Consider A Hydraulic Air Compressor?

Operators with hydraulics who want to add air power are the best candidates for a hydraulic air compressor. Of course, a vehicle upgrade that includes new hydraulics and a new air compressor is also a great fit. In either scenario, a hydraulic air compressor will take advantage of the existing hydraulic system with a clean, straightforward install.

Historically, hydraulic air compressors were almost exclusively used on trucks with hydraulic cranes. But the mobile air industry is rapidly innovating, and hydraulic air compressors are now found on excavators, including hi-rail excavators, pile drivers, and other specialized hydraulic equipment. Operators who work with an of these machines should consider a hydraulic air compressor when adding air power to their equipment.

Historically, hydraulic air compressors were almost exclusively used on trucks with hydraulic cranes. But the mobile air industry is rapidly innovating, and hydraulic air compressors are now found on excavators, including hi-rail excavators, pile drivers, and other specialized hydraulic equipment. Operators who work with an of these machines should consider a hydraulic air compressor when adding air power to their equipment.