Easy Guide To Rotary Screw Air Compressors (2024 Edition)

Rotary screw air compressors operate by trapping air between two meshed rotors and reducing the volume of that trapped air as it moves down through the rotors. This reduction in volume results in compressed air, which can then be used to power air tools, inflate tires, or in numerous other applications.

Rotary screw air compressors operate by trapping air between two meshed rotors and reducing the volume of that trapped air as it moves down through the rotors. This reduction in volume results in compressed air, which can then be used to power air tools, inflate tires, or in numerous other applications.

In this guide to rotary screw air compressors, we tell you everything you need to know, including:

- Intro to Rotary Screw Air Compressors

- Oil-Injected vs. Oil-Free Rotary Screws

- Air Compressor Components

- Basic Functions & Operation

- Power Sources For Mobile Air Compressors

- CFM & PSI

- Advantages of Rotary Screw Air Compressors

- Disadvantages of Rotary Screw Air Compressors

- Types of Rotary Screw Air Compressors

- Manufacturing Rotary Screw Air Compressors

Intro to Rotary Screw Air Compressors

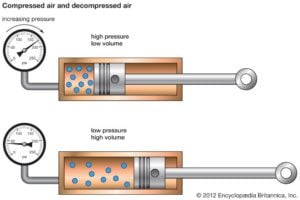

When most people think of air compressors, they picture reciprocating air compressors, also known as piston air compressors. These air compressors use pistons to push air into a smaller space, compressing it, and then that compressed air is collected in an air receiver tank. Reciprocating air compressors are relatively inexpensive and have been around for decades.

- Figure 1: Pistons Compressing Air

- Figure 2: VMAC’s 10,000th rotary screws

Rotary screw air compressors are a newer, improved type of air compressor. They can be more expensive than traditional reciprocating models but have numerous benefits that make rotary screw air compressors the system of choice for service truck and van fleet managers worldwide.

Rotary screw air compressors operate by trapping air between two meshed rotors and reducing the volume of that trapped air as it moves down through the rotors. This reduction in volume results in compressed air, which can then be used to power air tools, inflate tires, and more.

You can learn more about rotary screw versus other types of air compressors in these articles:

- Types of Air Compressors For Your Industrial Engine

- Performance Differences of Rotary Screw vs. Reciprocating Air Compressors

- Reciprocating Engine Driven Air Compressor or A Rotary Screw Engine Driven Air Compressor?

Oil-Injected vs. Oil-Free Rotary Screws

Rotary screw air compressors used on trucks and vans are oil-injected, which means oil lubricates and seals the rotors in the air end. This lubrication allows the rotors to create high pressures quite quickly and compress air in a single stage. The oil then gets separated from the air before the air exits the system and is recycled back into the air end for reuse. Oil-injected rotary screws allow the compressor systems to provide high CFM and psi continuously.

Oil-free rotary screw models are used in industrial, production, or medical applications when no oil can enter the airflow, like food packaging or medical oxygen. Oil-free rotary air compressors are more expensive, as they require two stages of compression to reach the same pressures as an oil-injected rotary system. Most companies only use oil-free rotary screw air compressors when they absolutely need to, so oil-free air compressors aren’t typically found on vehicles.

This guide is dedicated to rotary screw air compressors used on vehicles and therefore focuses on oil-injected rotary screws by default.

Air Compressor Components

Air Ends

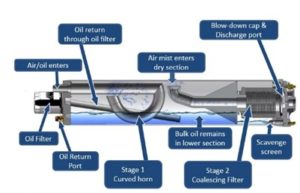

Many components comprise an air compressor, but the system's heart is the air end, where air is compressed. An oil-injected air end looks like this:

- Figure 3: Internal view

- Figure 4: External view

Air enters the air end through an inlet valve, where it is mixed with oil while being compressed. The oil is later separated from the compressed air, before it exits the system.

While air compression happens at the air end, many additional components are required to make a rotary screw air compressor work. These components are outlined below. You can also learn more about how the air compressor system works in the Basic Functions & Operations section of this guide.

Other Common Components

Air Filter

Figure 5: Air filter

The quality of air entering your compressor will affect the longevity of your system, so it’s important to use an air filter suited for the environment and the air flow.

That air filter can be mounted directly to the compressor or remotely mounted and connected with an air intake hose. Cool, clean air should be considered when choosing the location of the filter.

Primary Separator Tank

Figure 6: Primary separation filter

When compressed air leaves the air end, it mixes with compressor oil. This mixture enters a primary separator tank, where the first steps in separating the oil from the air occur. The primary separator tank uses mechanical separation and centrifugal force to drive oil molecules together, which form droplets that eventually fall to the bottom of the tank. A large amount of oil is removed from the air at this stage. Often, the separator tank also acts as an oil reservoir.

Secondary Separation Filter

Figure 7: Secondary separation filter

Compressed air is nearly oil-free once it leaves the primary separation tank. The remaining oil mist mixed with the air will enter the secondary separation filter, a coalescing filter. This filter includes a membrane material that gathers the remaining oil particles and circulates the oil back into the primary oiling system. The air leaving the coalescing filter is considered oil-free.

The secondary separation filter can be attached to the primary separation tank or mounted remotely on its filter manifold. Figure 6 includes the primary separation filter (labeled Stage 1) and the secondary separation filter (Stage 2).

Oil Filter

Figure 8: Oil filter

A rotary screw air compressor system must include an oil filter because it has a closed-loop oiling system. The oil filter’s job is to collect any loose particles in the oil that shouldn’t re-enter the air compressor system. The oil filter may be located on the compressor, the separator tank, or mounted remotely on a filter manifold.

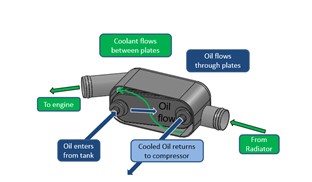

Oil Cooler

Figure 9: Oil cooler

The process of compressing air generates heat! This heat warms up the oil, which must pass through a cooler before it circulates back to the compressor. A liquid-to-liquid cooler can be used in conjunction with an engine's cooling system, or a standalone air-to-liquid cooler can be used instead.

The liquid-to-liquid version will need sufficient cooling capacity to cool the compressor oil and the engine. The air-to-liquid cooler will need clean, cool air to keep the oil within an optimal temperature range.

Figure 10: Air compressor hose

Hoses

Moving oil and air between various air compressor components requires the use of hoses. The hoses must meet the requirements of heat, pressure, and the compressor oil’s chemical components. Incorrect hose selection will result in premature failure of those hoses, which can be expensive and dangerous.

Figure 11: VMAC hydraulic system control

Controls

Air compressors will use mechanical or electrical controls like a button, switch, or lever. These controls will turn the air compressor off and on and may also provide important diagnostic or service information. The location and type of components used in the controls should reflect the environment the air compressor will be in.

Oil

Figure 12: Synthetic oil

Oil is a critical component of an oil-injected rotary screw air compressor, performing many important jobs at once. Oil lubricates the system, protects components from wear, keeps the system cool, and helps trap and remove contaminants. Without the correct type of synthetic oil, oil-injected rotary screw air compressors would not function.

The components listed above are necessary, in some form, for a rotary screw air compressor system. Many more options exist for filter manifolds, coolers, oil separators, etc. Each air compressor design and its required components are a bit different.

Encapsulated Air Ends

Figure 13: Encapsulated air end

Some manufacturers use encapsulated air ends, which combine several components within the air end’s metal casing, such as the rotors, intake valves, and separators, in a single package. However, encapsulated air ends are bulky and restrictive, presenting design challenges for air compressor manufacturers, vehicle upfitters, and OEMs. The combined pieces result in an inflexible shape that must be accommodated.

When manufacturers choose not to combine multiple components within an encapsulated air end, they can design smaller systems with more efficient designs without compromising on power or efficacy.

Basic Functions & Operation

Rotary screw air compressors are pressurized systems comprising many interconnected components that work together to compress air.

Air and oil are essential aspects of many rotary screw air compressor systems. Compressed air is the end goal, which requires atmospheric air, but synthetic oil is just as essential. Oil is used to lubricate the system and is the not-so-secret weapon that makes rotary screws so efficient at a lower price point.

But the use of oil also makes the air compressor systems more complex. In addition to requiring a mechanism for producing compressed air, rotary screw air compressors also need to circulate, filter, and recycle oil.

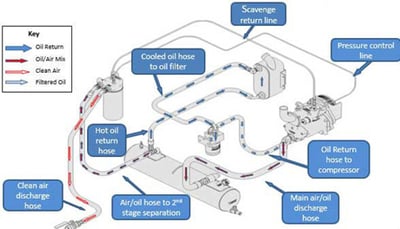

Two separate systems work together; one makes air, and the other circulates oil. The combined systems look something like this:

Figure 14: Air compressor system flow

A step-by-step guide to the system flow can help explain how the air and oil processes flow together within a single cohesive system:

System Flow Process

Step 1: Atmospheric air enters the inlet valve.

Step 2: Air flows through the system pressure line to a valve on the regulator, which sets the pressure for the entire system.

Step 3: Air is mixed with oil and compressed via the rotors in the air end.

Step 4: Air mixed with oil exits the air end via the air discharge hose.

Step 5: Air mixed with oil enters the primary oil separator tank, separating most of the oil from the air.

Step 6: Air enters the secondary separation filter, catching the remaining oil mist in the air.

Step 7 – A: Oil-free air exits the system; if an air receiver tank is used, the air collects in the tank.

Step 7 – B: Oil is moved into the oil cooler, cooled down, and sent to an oil filter.

Step 8: The oil filter catches any debris remaining in the oil.

Step 9: The recycled oil returns to the air end via the scavenge return line.

Note that visualizing the process as steps makes it easier to understand the overall flow, but these steps operate concurrently. When the air compressor is turned on, all the above steps occur simultaneously and continuously.

Power Sources For Mobile Air Compressors

Air compressors need a power source to run. Fortunately, vehicle-mounted air compressors have several options: a separate air compressor engine, using a truck’s existing engine, or tapping into an auxiliary power source like a PTO or hydraulic port.

For example, here’s a breakdown of VMAC’s rotary screw air compressors and their power sources:

| VMAC Air Compressor / Multi-Power System |

Power Source |

| G30 Gas Driven | Standalone Gas Engine |

| D60 Diesel Driven | Standalone Diesel Engine |

| Multifunction 6-in-1 | Standalone Diesel Engine |

| H40/H60 Hydraulic Driven | Hydraulic Port |

| Direct-Transmission Mount | PTO |

| UNDERHOOD® | Gas or Diesel Vehicle Engine |

In summary, there are many power options for mobile air compressors. The right one depends on a truck or van’s existing power options and whether they will work with an air compressor that provides enough CFM and psi. Vehicle engine mounted and hydraulic air compressors are convenient, while standalone engines are efficient and cost-effective.

CFM & PSI

In North America, compressed air power is measured using CFM and psi. CFM or “Cubic Feet per Minute” is the amount of air delivered, while psi or “Pounds per Square Inch” is the amount of force behind that air. Together, CFM and psi identify how much air is being delivered and at what pressure. Air tools require the right CFM and psi to operate efficiently.

Rotary screw air compressors tend to produce lower psi than reciprocating air compressors, but this isn’t a problem for most mobile air applications. Most air tools run at 80 to 110 psi, which is well within the capabilities of rotary screw air compressors.

Find out more about CFM and psi in these two articles:

Advantages of Rotary Screw Air Compressors

Rotary screw air compressors have many benefits that make them ideal for mobile and standalone applications. As a result, you’ll find rotary screw air compressors on vehicles and trailers and in industrial, production, and medical facilities, where high-quality equipment is required.

The benefits of rotary screw air compressors over other compressor types include:

- Continuous airflow/100% duty cycle

- Larger quantities of air

- Higher CFM per hp

- Longer lifespan

- Better warranties

- Quieter

- Energy efficient

Most people appreciate rotary screw air compressors because of their longevity, reliability, and easy access to instant air. Because rotary screw air compressors can run continuously, there’s no need to wait for an air receiver tank to fill before you can start using the air. Those tend to be the most popular benefits of rotary screw air compressors.

Many operators also appreciate the limited lifetime warranties that come with some rotary screw air compressors, like VMAC’s. These warranties are available because the rotors and air ends are proven to stand the test of time—or, more specifically, the life of a modern service truck. This longevity makes rotary screw compressors a drama-free option.

For example, the first VMAC rotary screw air end outlived the truck it was installed on. The rotors were returned to us and are on display in our trophy case.

Figure 15: VMAC’s first rotors, which outlived the truck

Rotary screw air compressors’ lengthy lifespan is a considerable advantage over reciprocating air compressors, which are jokingly referred to as “throw-away air compressors” because they often fail after 3 to 5 years.

Disadvantages of Rotary Screw Air Compressors

Rotary screw air compressors have a lot of advantages, but they aren’t the right choice for everyone. Common rotary screw air compressor disadvantages are:

- Upfront cost

- Skilled maintenance required

The initial cost is the primary reason people choose a reciprocating air compressor over a rotary screw. Rotary screw air compressors often cost twice as much as reciprocating air compressors, but it’s a situation where you genuinely get what you pay for.

Rotary screw air compressors may be 2x the cost, but they last at least 4x longer, on average, and produce more air. That makes them a solid investment for any business that plans to use compressed air over the long term.

The other disadvantage of rotary screw air compressors is they require skilled maintenance. Every type of air compressor needs regular servicing, but the complex nature of rotary screw systems requires a higher level of expertise.

Types of Rotary Screw Air Compressors

Many types of rotary screw air compressors are utilized on vehicles in mobile applications. VMAC’s air compressor systems demonstrate the range of rotary screw compressor options for vehicles.

UNDERHOOD® Air Compressors

Figure 16: Installed UNDERHOOD 70 air compressor

UNDERHOOD air compressor systems are one of the coolest options out there, as the air compressor components integrate with the existing truck or van components. The air end mounts in the engine compartment, and the vehicle’s existing engine powers the compressor system. UNDERHOOD air compressors are super light and weigh only 62 to 200 lb, saving precious GVW and cargo space.

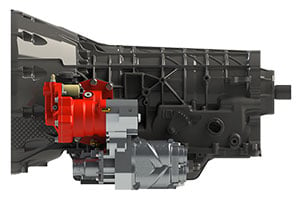

Direct-Transmission Mounted Air Compressors & Multi-Power Systems (DTM)

Figure 17: 3-D Render of DTM70 on Ford Transmission

The Direct-Transmission Mounted air compressor uses a vehicle’s PTO to drive the air compressor. Similar to UNDERHOOD, the DTM is a lightweight “out of sight” option that integrates with a vehicle’s existing components.

Gas Driven Air Compressor (G30)

Figure 18: G30 Gas Driven Air Compressor

The G30 gas driven air compressor has a separate Honda GX390 gas engine, like you’d find in a ride-on lawnmower or other small vehicles. This style of air compressor mounts to a truck or van and can be used by any operator with the key.

Diesel Driven Air Compressor (D60)

Figure 19: D60 Diesel Driven Air Compressor

VMAC’s D60 is a diesel driven air compressor with its own Kubota diesel engine. Similar to the G30, these straightforward air compressors are also easily mounted to a work vehicle.

Hydraulic Driven Air Compressor (H40/H60)

Figure 20: H40 Hydraulic Driven Air Compressor

Vehicles with existing hydraulic systems can tap into those systems to power their air compressor. The VMAC hydraulic driven air compressor makes sense for operators with hydraulic cranes and other hydraulic-powered equipment.

Multifunction Power Systems

Figure 21: VMAC Multifunction Power System

Multi-power, all-in-one, or multifunction systems are now a popular option offered by some manufacturers. In one convenient system, multi-power systems combine air compressors with other vehicle-mounted equipment, such as welders, generators, and boosters. VMAC’s Multifunction Power systems are powered by a Cat or Kubota diesel engine.

Electric Air Compressors

EV manufacturers are still racing to see who can develop the first market-dominating electric service trucks and vans and there is no clear EV or electric air compressor winner yet. However, as electric trucks and vans gain popularity within the service truck industry, further development of these technologies is inevitable; VMAC is currently field-testing electric air compressor technology for a range of applications.

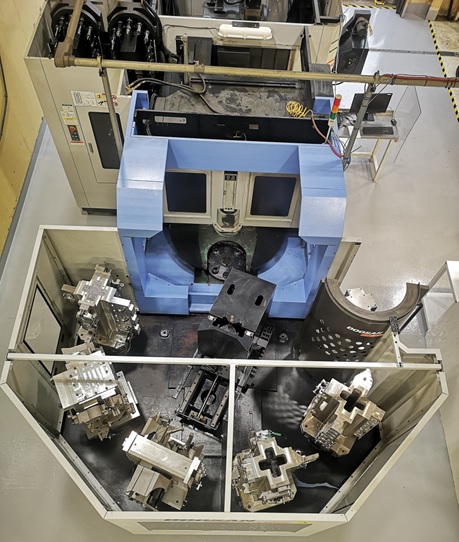

Manufacturing Rotary Screw Air Compressors

Rotary screw air compressors are comprised of numerous components assembled into a highly efficient system. Authentic air compressor manufacturers will create these parts within their facilities, using an in-house foundry, CNC machines, and other specialized equipment to make the required components. Individual components are then assembled on-site into an air compressor system.

Figure 22: Crucible & furnace in VMAC’s foundry

Figure 23: Aerial view of A CNC machine at VMAC

Figure 24: VMAC’s coordinate measuring machine

Design Tolerances

When engineering and manufacturing parts for any system or machine, there is an acceptable margin of error called tolerance.

The required dimensions for air ends in rotary air compressor systems are so precise that these tolerances are incredibly low. Computer Numerical Control machines—CNC machines, for short—allow manufacturers to meet the exact tolerances needed for rotary screw air compressors.

For example, these are the maximum tolerances VMAC allows for parts made with CNC machines in comparison to the parts made using manual machines:

| Maximum Tolerance | Suggested Tolerance | |

| CNC Mills | ±0.0003 | ±0.005 |

| CNC Lathes | ±0.0003 | ±0.005 |

| Manual Mills | ±0.001 | ±0.005 |

| Manual Lathes | ±0.001 | ±0.005 |

Stringent quality control processes ensure the required tolerances for each machine are met. If a machine fails to produce parts within the acceptable tolerance, those parts are melted back down or otherwise recycled. The designs and machines will also be evaluated and adjusted as needed.

Fortunately, manufacturers using modern quality control technology can predict when a CNC machine will need to be calibrated well in advance and plan maintenance accordingly.

Authentic Manufacturers vs. Assembly Companies

One significant advantage to making parts on-site is that the parts can be modified at will. Instead of being restricted by existing component shapes and sizes, genuine manufacturers can innovate on individual parts on their desired schedule, creating more efficient, powerful and compact air compressor systems.

A more common type of air compressor manufacturer will purchase existing parts from suppliers or, less often, contract their creation out to external companies. If a custom part is required, these air compressor companies must book space with third-party foundries, machinists, and so forth and then rely on their general expertise for modifications. This style of air compressor manufacturer assembles pre-purchased pieces into air compressors before shipping them out to customers.

VMAC is one of North America's only authentic rotary screw air compressor manufacturers.