Membrane Type Dryer

Membrane type dryers are the perfect air dryer if CFM flow rates, inlet pressures and maximum inlet temperatures fall within its sizing limitations. The dryer design is simple with no moving parts, requires no electrical energy, and needs only minimal ongoing maintenance. Combined with exceptional moisture removal, a membrane dryer is the perfect choice for most low-flow unattended applications.

However, membrane dryers are not practical for all air dryer applications due to their lower CFM capability. Most membrane dryers are designed for applications with 0-30 CFM, although some higher applications can exceed 150 CFM with the right temperatures. Membrane dryers also require oil-free air.

How A Membrane Dryer Works

The membrane dryer is a point-of-use dryer that operates on the principle of selective permeation through a membrane. The membrane dryer can be connected in parallel to increase the capacity beyond that of the single dryer.

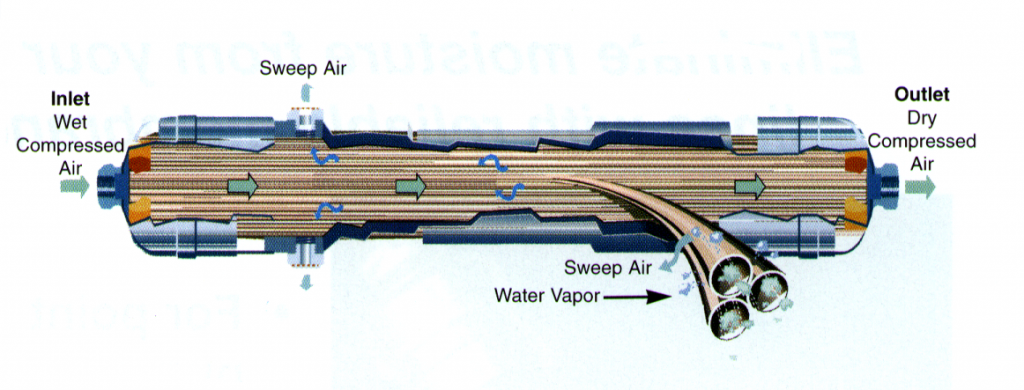

As the compressed air passes through a bundle of tiny hollow (polysulfone) membrane fibers, water vapor is separated by the differential gas pressure on the inside and outside of the hollow fibers. This water vapor and a portion of the compressed air flow diffuses through the semi-permeable membrane walls while the dried air continues downstream.

The water vapor which has been separated from the compressed air is purged out of the housing by the sweep air (Purge air).

Important Considerations Of Membrane Dryers

Membrane dryers are relatively low maintenance dryers, but they do have some important considerations and guidelines. To start, membrane dryers must be used only with clean, oil free air.

Membrane dryers also require a coalescing type prefilter installed ahead of the dryer to remove any liquid water, oil and aerosol contaminants from the compressed air stream. Contaminants block the permeations of the fibers, reducing the performance of the dryer. It is critical to the life expectancy and performance of the dryer that the pre-treatment coalescing filters are correctly sized and maintained.

Membrane Dryer Advantages

- No moving parts.

- No consumables to replace.

- No external power source required.

- Installs directly in the pipeline.

- Can operate in severe environments, such as high or low temperatures or corrosive and explosive atmospheres.

- Operates continuously without the need for adjustment or maintenance (except prefilter maintenance).

- Dewpoint suppression range is between +40 and -40°F.

Membrane Dryer Disadvantages

- Best suited for low CFM applications; typically below 80 CFM

- Requires about 15-20% purge air (on some models).

- Reduces the oxygen content of the compressed air and cannot be used in breathing air applications.

- Not compatible with oil-injected applications.

Ready to learn about another type of dryer? Check out the Deliquescent Dryer in this post!