The Deliquescent Dryer

The deliquescent drying system is a portable compressed air drying package used mainly for media blasting and painting contractors doing metal surface preparation work.

The deliquescent drying system is a portable compressed air drying package used mainly for media blasting and painting contractors doing metal surface preparation work.

Deliquescent driers have also been used extensively in outdoor construction applications with engine driven portable air compressors where no external power source is available to run other types of air drying equipment.

How A Deliquescent Dryer Works

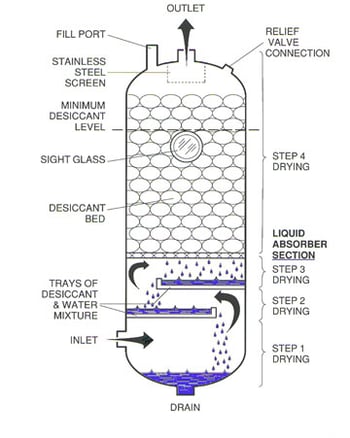

Incoming air enters the vessel near the base and passes through the mechanical separation section. Due to expansion, the free liquids and solids drop to the bottom of the vessel, which somewhat pre-dries the air.

The air then enters the desiccant bed of deliquescent materials such as water-soluble salts or shotted urea. The hygroscopic chemicals condense water vapor as they deliquesce or dissolve. The tablets will absorb water until they are full and must be replaced.

Pros & Cons Of Deliquescent Dryers

Deliquescent dryers have numerous advantages and disadvantages, which must be considered when deciding whether they suit your compressed air system.

Advantages:

- Lowest initial cost of all dryer types

- No electrical hook-up

- No moving parts

- Simple operation

Disadvantages:

- Dewpoint suppression is between 20º to 30º F (on average)

- Deliquescent material must be added to or replaced as it absorbs and melts

- Ecological problem of disposing of the dissolved deliquescent material

- Cost of replacement deliquescent and of disposal of dissolved deliquescent material

- Carryover of corrosive deliquescent materials into the downstream piping network

and air - Parts of the deliquescent materials can solidify in the bed and cause channels for the air to bypass most of the drying material, which reduces the dryer’s performance

Additional Components & Considerations

The principles of operation for deliquescent moisture absorption are very simple, as described above, but there are additional components required for the system to function properly.

Additional system components include:

- An inlet coalescing pre-filter to prevent oil carryover from the compressor from entering the dryer and contaminating the drying material

- A particulate-style after-filter to prevent air dryer media carryover from damaging downstream equipment

- A mechanical drain to remove water and liquify dryer media from the dryer tank

As with any air dryer, the cooler the inlet air is as it enters the dryer, the better it will perform. Therefore, some type of compressed air aftercooler is recommended as well.

Dewpoint Suppression

There are several different types of media that can be used in a deliquescent dryer, each offering different levels of drying capacity, or dewpoint suppression. It is important to note that the air temperature at the point of use must stay within the suppressed dewpoint available, or water will form in the outgoing air.

Dewpoint suppression is impacted by many factors:

- Age and composition of the deliquescent material

- Compression of the tablets

- The vessel configuration

- The compressed air inlet temperature

- The compressed air velocity (based on pressure)

With so many factors to consider, you may need to consider several deliquescent dryers before you find the right one for your compressed air system.

Interested in other types of dryers? Learn about the Membrane Type Dryer here!