VMAC Develops Tiny 30 CFM Air Compressor With Ogura Clutch

Commercial van manufacturers changed the game forever in 2015 with new Euro-style vans in North America, including Ford’s 3.7 L Transit, Mercedes Benz’s 3.0L Sprinter, and the Ram 3.6L ProMaster. These vehicles boosted fuel efficiency and dramatically increased cargo space, causing shake-ups in the mobile service industry.

Commercial van manufacturers changed the game forever in 2015 with new Euro-style vans in North America, including Ford’s 3.7 L Transit, Mercedes Benz’s 3.0L Sprinter, and the Ram 3.6L ProMaster. These vehicles boosted fuel efficiency and dramatically increased cargo space, causing shake-ups in the mobile service industry.

While these vehicles offered state-of-the-art engines, reduced emissions, and roomy vehicle platforms, they also significantly reduced the space under the hood, creating a new challenge for developing engine-driven aftermarket components including air compressors.

Fortunately, VMAC developed a solution: UNDERHOOD® LITE. Utilizing Ogura’s small size, high torque electromagnetic clutch, UNDERHOOD LITE air compressors meet performance and cost reduction goals that were previously unobtainable.

Challenges of Designing A New Mobile Air Compressor For Vans

North American commercial vehicle regulations have made vans a necessary option for many fleet managers, but unfortunately, commercial vans lacked an adequate solution for running air tools.

Until now, mobile air choices for vans have been limited to electric or gas engine-powered compressed. Electric air compressors produce very small CFM, which aren’t suitable for many air tools. Meanwhile, gas engine-powered compressors mounted in the van take up significant room, must be vented for exhaust and gas fumes (which is often done improperly), and pose safety hazards while filling the fuel tank.

As engine compartment space becomes more limited, manufacturers like VMAC faced the challenge of designing a system that would fit into the small location usually reserved for the second alternator. Even traditional engine mounted air compressor systems, such as VMAC’s industry leading UNDERHOOD70 system, simply would not fit on these new platforms.

To overcome this challenge, revolutionary compact innovations were demanded in three areas: the air compressor, its electromagnetic drive clutch, and the oil cooler and separator.

Challenge 1: Air Compressor

VMAC’s first challenge was fitting the compressor in a space design for a vehicle alternator. VMAC had to start with a blank slate and broke a number of traditional compressor design norms to achieve the goal.

A unique, patented air intake through the front of the rotors helped keep the envelope size compact. Meanwhile, using a check valve instead of an inlet valve reduced space and simplified the design.

As in life, timing is everything. The call for a smaller air compressor began several years ago in 2009 when VMAC’s customers and Dealers requested a smaller, half cost, and half output version of their popular UNDERHOOD70.

This early research gave VMAC a fortuitous five-year start to perfecting a solution for a problem that didn’t even exist at the time. Wrapping up that initiative allowed the team to create the 30 CFM air compressor needed for the UNDERHOOD LITE system.

Engineering Breakthrough: VMAC's Journey To Halve The Cost & Output Of UNDERHOOD70

It was a crisp fall day in 2009 at the Kiwi Lodge in Nanaimo when VMAC’s Dealer Advisory Group challenged VMAC to design an UNDERHOOD Air Compressor that was ‘half the cost and half the output’ of the UNDERHOOD70. As a company staffed with design engineers and a state-of-the-art manufacturing facility, the gauntlet had been thrown down and was quickly picked up.

The challenge would involve many aspects of the air compressor system, not just the individual components, as a reduction in the output of a rotary screw compressor does not result in a proportional cost decrease.

A key design feature of the 70 CFM system is the addition of a dedicated second pulley (and belt) mounted to the OEM engine crank pulley. This feature is designed to handle side-loading issues on the accessory bearings in the belt line. A smaller output compressor would likely not affect the OEM components loads and the idea to run the compressor off the existing OEM single accessory drive belt was born.

A team of engineers were tasked to use an existing UNDERHOOD70 compressor and create a prototype of a gearless version to meet the lower output and lesser cost scope. This was quickly done, and a bracket design was manufactured to mount on one of the company vehicles to see if using the OEM belt was feasible.

Initial testing proved that this concept was a winner in terms of reducing the number of components, cost of the compressor and reducing the output. But there was still work to be done as VMAC’s former President Jim Hogan added two new requirements to be tackled in the years ahead:

First, design the compressor to fit in the small space of the Ford SuperDuty 6.7L PowerStroke Diesel’s second alternator position. Second, draw inspiration from the simple controls and operation of an early under the hood reciprocating compressor design by Francis L. Zrostlik’s, co-founder of Iowa Mold Tooling and Stellar Industries.

With the compressor in hand, VMAC engineers quickly designed a small bracket for the 6.7 PowerStroke alternator position. It fit perfectly into that alternator position. The second requirement was also fulfilled with the help of Ogura.

VMAC met the challenge, innovating mobile air in a way that was never seen before, and the result was introduced to the world with the launch of the UNDERHOOD LITE.

Challenge 2: Electromagnetic Drive Clutch & Pulley

Another key to the new UNDERHOOD LITE compressor design was simplifying the controls. VMAC decided to procure a unique clutch built by Ogura, the world’s largest manufacturer of electromagnetic clutches.

Ogura and VMAC already worked together for over a decade to provide “best in the business” electromagnetic clutches for UNDERHOOD70 air compressors. Tasked with a new challenge, Ogura went to work.

Ogura and VMAC already worked together for over a decade to provide “best in the business” electromagnetic clutches for UNDERHOOD70 air compressors. Tasked with a new challenge, Ogura went to work.

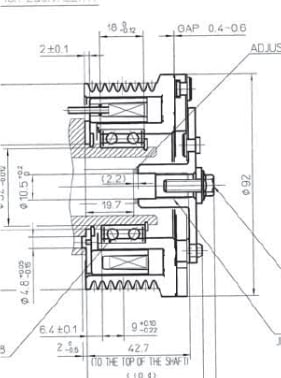

Ogura designed the world’s first 85 mm OD, 8 groove Poly V production clutch, capable of driving the anticipated pump loading (>15NM) at speeds exceeding 7,000 RPM. Meanwhile, the 85mm pulley enables the compressor to be effectively geared higher to reduce the offset in diameter of the OEM crank pulley in relation to VMAC’s 70 CFM designs.

The new Ogura clutch controls the compressor and was chosen to emulate Zrostlik’s simple reciprocating control system. The control system is simplified to include only basic components: an on/off, temperature and pressure switch and indicator lamp, two relays, and a simple one speed throttle.

The clutch also reduces the cost, size, weight and number of components being used, while improving life expectancy and simplifying assembly.

With the compressor and control system designed, the next step was set in motion.

Typical engine mounted automotive clutches (such as the popular AC compressor clutch) use multi-pole flux directing technology to increase magnetic clamping forces. It is this magnetic clamping force which creates torque to transmit power from the pulley to the compressor. Most multi-pole clutch flux directing techniques incorporate circumferentially linked air slots together with low carbon steel radial spokes evenly spaced in the clutch rotor (pulley input) and armature plates (output to air compressor) for strength.

While the steel spokes add radial strength to the pulley, they are a short (circuit) to the flux path. This short (circuit) reduces the efficiency of the magnetic system, and would yield lower torque from the clutch (lines of magnetic flux will pass through steel faster than through air).

For higher torque, Ogura’s MAE-MG43 clutch does away with traditional flux directing techniques by completely eliminating the steel structural spokes, replacing them with a structurally strong, but magnetically neutral material creating a near 100% efficient magnetic circuit. It is this marked increase in magnetic efficiency, with multipole technology that allows Ogura clutch to transmit the torque of a clutch nearly twice its size.

To provide long life and to handle the increase in clamping forces on the smaller diameter, the Ogura clutch integrates a stable high performance proprietary friction material embedded in the rotor pulley. This material is suitable for under hood environments, is impervious to typical contaminates such as water, antifreeze, engine oil and grease. The addition of friction materials in automotive clutches is not new for Ogura, it has been used in clutches on automotive superchargers for over 30 years with typical working speeds in excess of 15,000 RPM.

The clutch rotor is supported by a special NSK custom designed 47 mm OD double row ball bearing, lubricated for life. The unique snout mount bearing design keeps raceways constantly in motion and properly lubed (wither the clutch is engaged or not). The snout mount design eliminates bearing brinelling issues caused by extended engage times in some earlier clutch designs.

To help with quick assembly, disassembly (if needed) and solid torque transmission to the pump, Ogura’s JIS splined armature hub bore is center-tapped for easy installation to the pump shaft.

The following features make this clutch the most advanced miniature 8-groove, 12 VDC clutch available today:

- Multipole, spoke-less rotor design,

- Permanently lubricated, snout mounted, double row ball bearings,

- Robust proprietary friction material,

- Compact 85 mm pulley size,

- Bi-directional armature return springs

- Fully epoxy encapsulated coil (located within the pulley cavity)

Challenge 3: Oil & Air Separation

With the Ogura clutch prototypes designed, delivered, and in test, VMAC concentrated on the final parts of the new system.

VMAC wanted to improve total costs by designing components that would ease installation and reduce the time it takes to complete the job.

VMAC wanted to improve total costs by designing components that would ease installation and reduce the time it takes to complete the job.

The VMAC team revisited older experiments and a past idea of integrating cooling and oil separation into one package. Various designs were built and tested until a final candidate worked remarkably well.

VMAC’s introduction of the WHASP Tank was worthy of another patent as the company broke the mold on traditional thinking. This new tank removed the need to integrate into the vehicle’s cooling system, moved two components into one place, and made for a very quick install.

The first non-VMAC installers to work with the system took a mere five hours from start to running the compressor on a 6.7L installation. The reduction in install time alone saves the Dealer and end user a significant amount of cost.

A New Era For UNDERHOOD Systems

With all major components finalized, VMAC turned to a few dealers to move the product into the market. At this same time, the introduction of European style vans created a new major market in North America.

Looking back to that day in 2009 and the challenge thrown down by the Dealer Advisory Group, VMAC is confident the UNDERHOOD LITE with the Ogura clutch will enable its dealers to install a state-of-the-art, cost-effective rotary screw air compressor system under the hood of mobile service vehicles for current markets and new ones yet to come.

Note: The UNDERHOOD LITE product line was upgraded in 2018 to the UNDERHOOD40 product line.