Quick Links

Gas Powered Air Compressors & Air Compressor/Generators

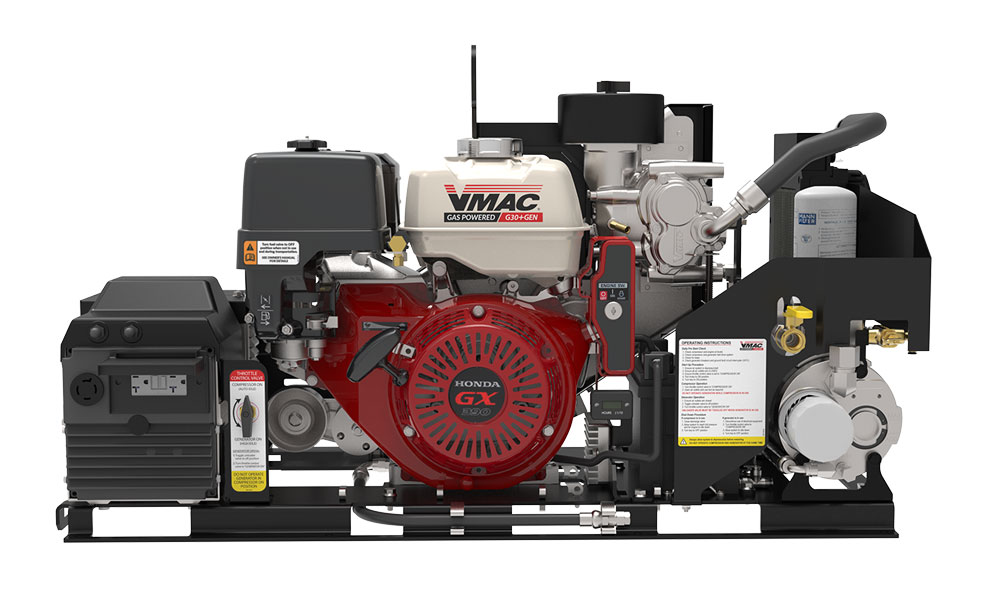

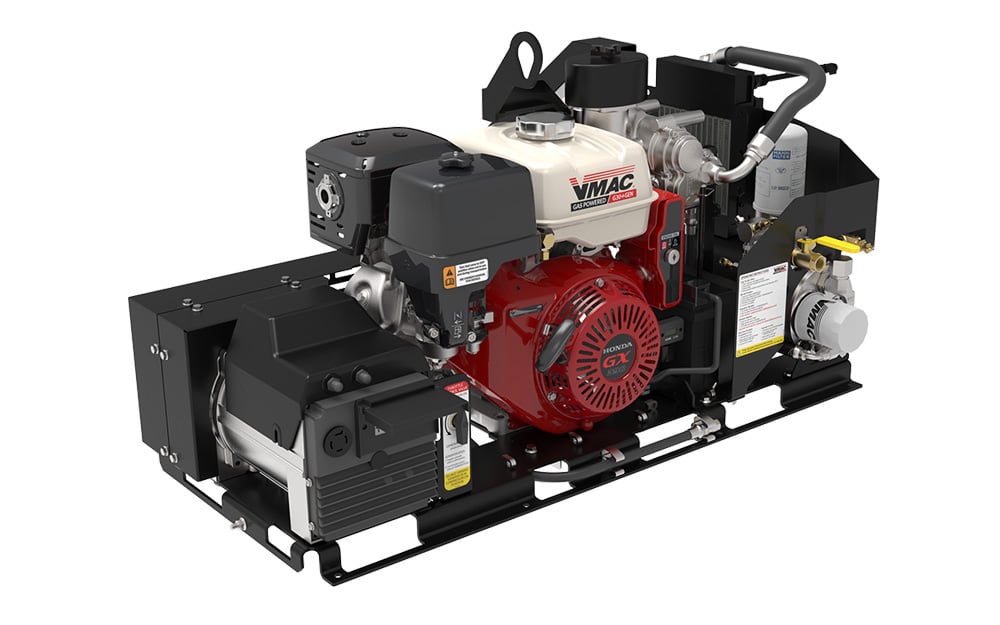

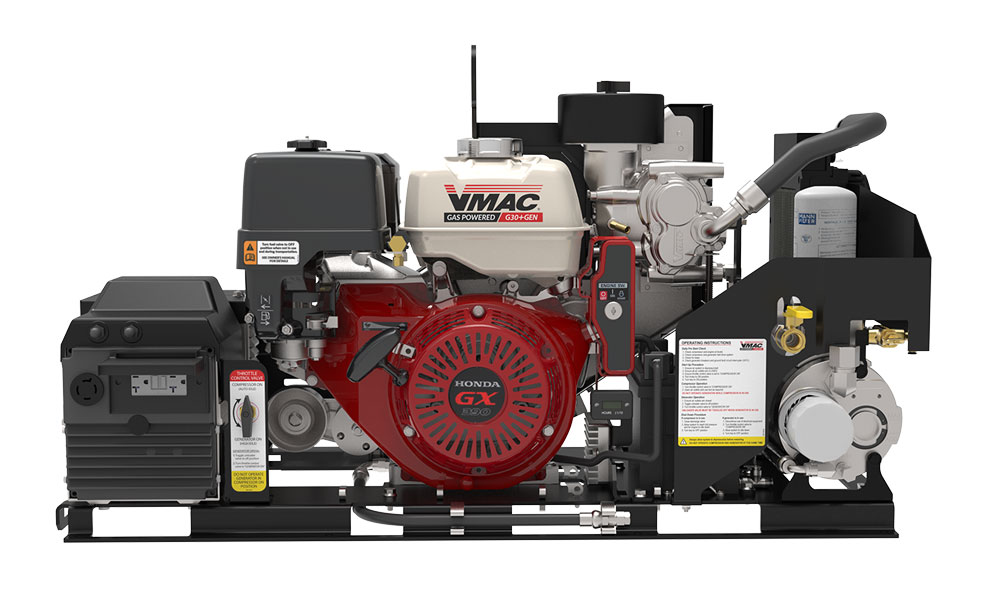

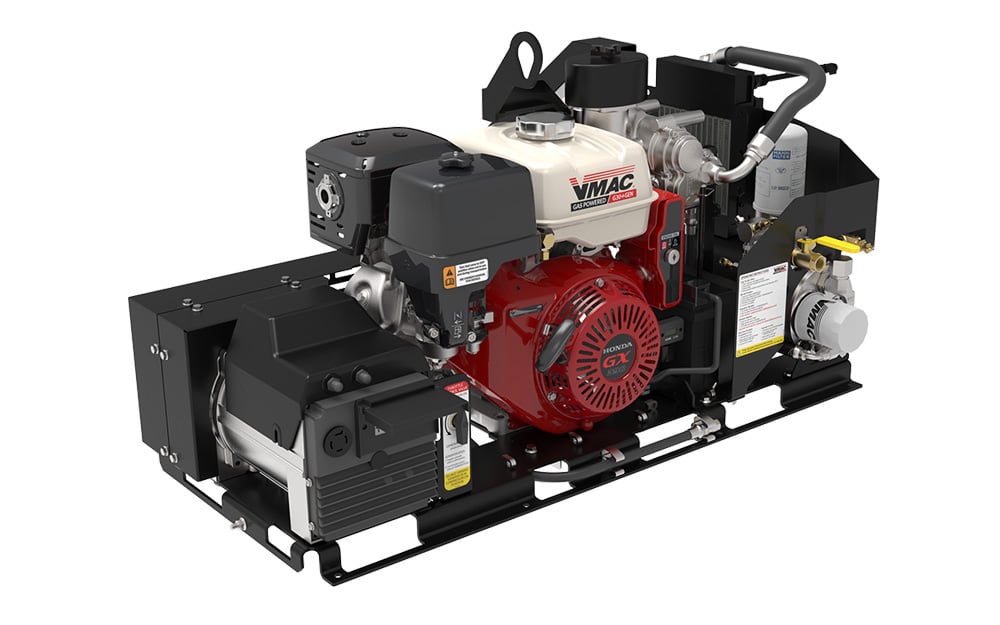

The VMAC G30 and G30+GEN, powered by Honda, are the most affordable gas powered rotary screw air compressors and air compressor/generators available.

The G30 is the best choice for fleet managers and owners who need the lightweight, compact performance of a rotary screw air compressor at the lowest price possible. The standard and stacked G30 air compressors deliver 30 CFM at 100 psi with 100% duty cycle, helping operators get their work done without interruption.

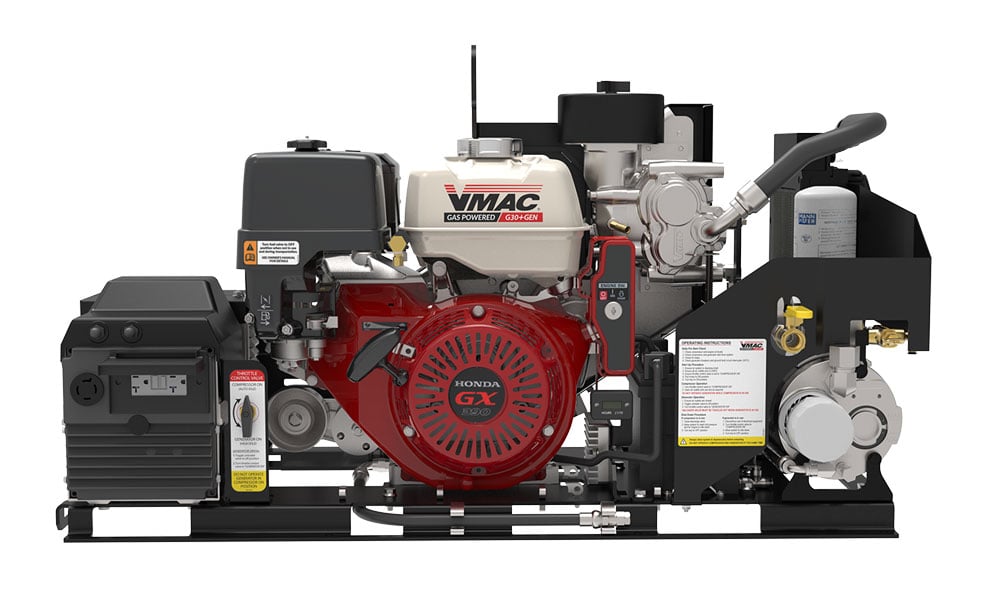

The G30+GEN combines two convenient forms of power into a single, innovative system. The G30+GEN delivers 25 CFM and 3600 W, allowing operators to quickly switch between air and AC power for their tools and equipment.

With three gas powered models available, fleet managers and owners can choose the G30 model that works best for their application, either with air or with air and AC power.

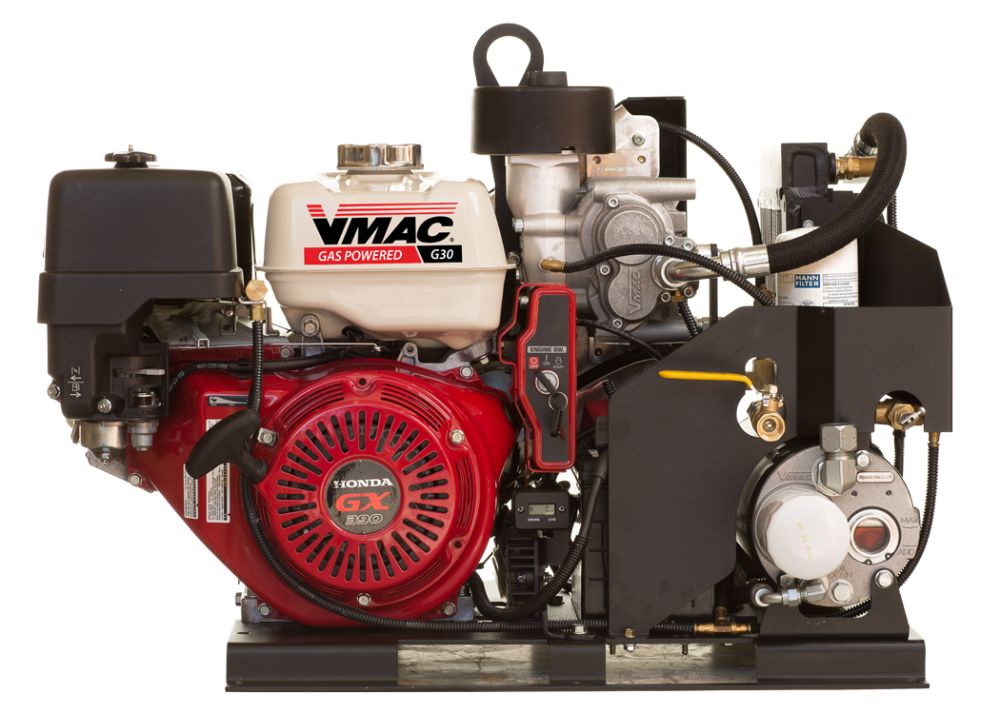

Gas Powered Air Compressors

The best choice for fleet managers and owners who need the lightweight, compact performance of a rotary screw air compressor, at the lowest price possible.

Stacked Gas Powered Air Compressors

The perfect choice for fleet managers and owners who want the smallest possible footprint on their work truck, without compromising on power or performance.

Gas Powered Air Compressor/Generators

Combines two convenient forms of power into a single, innovative system.

25-30 CFM, 100% Of The Time

VMAC standard and stacked G30 gas powered air compressors include a patented 30 CFM rotary screw air compressor, while the G30 air compressor/generator produces 25 CFM and 3600 W. These systems are designed to maintain max CFM 100% of the time, so operators don’t have to wait for their air compressor to fill up an air receiver tank. This maximizes air tool performance while providing maximum operator efficiency at the job site and eliminating downtime.

Over 50% Lighter & Smaller

VMAC G30 gas driven air compressors are engineered and manufactured for mobile applications. VMAC air compressors feature the latest rotary screw technology integrated into a compact, turn-key package that is significantly lighter and smaller than other gas powered air compressors and compressor/generator combos on the market today. With three models available, fleet managers and owners can choose the model that works best for their applications, either with air or with air and AC power, while fitting more tools, equipment and supplies on trucks without hassle.

Industry-Leading Reliability

VMAC G30 gas powered air compressors and compressor/generators are proven to work in extreme cold climates across North America when ordered with an optional, factory-installed cold climate kit. Engines supplied by Honda come with an industry-leading 3-year warranty and VMAC rotary screw air compressors come with the industry’s first Lifetime Warranty (Limited).

VMAC 30 CFM Gas Driven Air Compressor at work

Get all the power you need in this small air compressor. The G30 gas drive air compressor with 30 CFM rotary screw air power.

VMAC Stacked G30: Rotary Screw Gas Driven Air Compressor With Vertical Design

Join Darren Darnley from VMAC, as he goes through the specs, components, safety features, warranty and accessories of the G30.

VMAC 30 CFM Gas Driven Air Compressor Demo Video

The VMAC G30 Gas Engine Driven Air Compressor is now powered by Honda!